If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

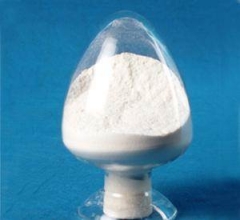

Calcium stearate (also known as calcium stearate) is a calcium sulfate that is produced from calcium oxide and stearic acids. It is used in food, cosmetics and plastics. The use of calcium stearate is not without its pros and cons.

Synthesis and use of calcium stearate

1. Synthesis of Calcium Stearate. The calcium chloride with a concentration of 1074kg/m3 (also known as 10degBe), is added to a sodium stearate preparation prepared earlier. Metathesis occurs at approximately 65degC. The precipitation process separates the calcium stearate. The finished product is obtained after it has been filtered, washed in water, and then dried at around 90degC.

2. In 300mL hot water at 55 degrees Celsius, dissolve 5.60g of calcium oxide (0.1mol). Pour 51.3g of chemically-pure stearic acids in 350mL water heated to 70degC. Add 0.7g of diethanolamine and stir it up. The prepared stearic-acid emulsion is added to the suspension of calcium oxide within 2h and thoroughly stirred. After that, the white, insoluble material, which is calcium stearate was filtered and dried.

3. Direct method: Add a certain quantity of stearic acids and CaO in a pot with a stirring device and thermometer. Heat it to melting, then add the catalyst slowly while constantly stirring. Apply a vacuum for the temperature to be controlled at 140-150degC. The reaction lasts 1.52.0h. The reaction is complete when the material has been discharged, cooled down, and crushed.

4. Metathesis method – Dissolve the stearic solution in 20 times as much hot water. Add caustic soda saturated solution. Perform saponification at approximately 75degC. This will generate a dilute sodium stearate. The calcium chloride with a 1074kg/m3 content was added, the metathesis was done at about 65 and the calcium stearate product was precipitated. Then, it is filtered and washed in water before being dried at around 90degC.

Calcium stearate applications

Calcium stearate has many uses, including as a heat stabilizer for polyvinylchloride, a lubricant used in plastic processing, or a mold release. When mixing lead soap with basic salt, it can accelerate the gelation process.

The non-toxic film and appliance, such as medical equipment and food packaging, also uses calcium stearate. Calcium stearate may also be used in polyethylene or polypropylene as a halogen-absorbing agent to reduce the harmful effects of residual catalyst on color stability and durability.

Calcium stearate can be used as a rubber plasticizer to soften rubber. It has a minimal effect on vulcanization. It is used in the production of plastic records as well as a lubricant, waterproofing agent, paint flattener, thickening agent, and for polyolefins fibers. As a halogen absorbent for polypropylene and polyethylene; as a release agent and lubricant in thermosetting plastics like phenolic, amino and acrylic; as lubricant or thickening agents for grease; as waterproofing agents for waterproof fabrics; as an agent of flattening for paint; and as lubricant to remove pencil lead. Anticaking agents are made from food-grade Calcium Stearate.

Calcium stearate can also be used to make pencil lead and in medicine.

(aka. Technology Co. Ltd., a trusted global chemical supplier and manufacturer of high-quality nanomaterials with over 12 year’s experience, is a trusted source for super-high quality chemicals. Boron Powder produced by our company is of high purity and has a low impurity level. Contact us if you need to.