If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

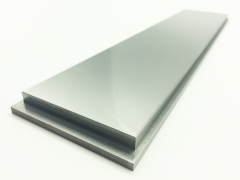

chromium cobalt is an alloy of cobalt and chromium developed more than a half century ago. It is machinable and malleable, but has amazing strength and is very hard to break, bend or deform. It also has appealing white color and shine that resembles precious metals like platinum or gold, making it a popular material for jewelry.

Cobalt chromium is used with many surgical implants, including femoral components in total hip replacements and femoral heads for acetabular cups. However, it has limited use in the spine because it is not very MRI compatible. Recent research has shown that cobalt chrome can be successfully incorporated with titanium rods for spinal fusion. However, there is still a lack of MRI studies on these devices to evaluate artefacts generated in postoperative MRI.

The aim of this study is to investigate the effects of conventional and laser welding on the tensile strength, ultimate tensile strength and surface characteristics of two different cobalt chromium alloys. Rod shaped specimens were cast from the two cobalt chromium alloys (Wironium plus and Diadur). The specimens were then sectioned and welded using electric brazing and pulsed Nd: YAG laser welding. The welded samples were subjected to tensile testing and scanning electron microscopy.

Cobalt chromium is a hard and expensive metal that is challenging to machine. The machining process generates high cutting temperatures, which can shorten tool life and produce poor surface quality. The purpose of this study is to examine the effects of different oxidation heat treatments (OHTs) on the bond strength between a ceramic and both cast and milled cobalt chromium alloys.