If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

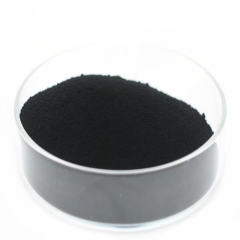

Carbon fiber is a very strong material. It is used to make high-performance car parts such as the engine block. The parts are extremely light, making them more efficient than the traditional metal ones. They also have a better strength-to-weight ratio than steel and plastic.

Carbon fibers are made by heating a precursor material, which is usually PAN (Polyacrylonitrile), or other organic materials like petroleum pitch and rayon. Several cycles of heating at varying temperatures and excluding oxygen are used to modify the chemical structure of the precursor and allow for the formation of tightly-bonded carbon crystals in the finished carbon fiber.

The carbon fibers can be shaped and stretched into various shapes. They can be woven together to form fabrics, which are then used to create composites. Carbon fibers can have a uni-directional or one-direction weave, depending on how the product will be used. This allows the designer to get maximum stiffness in certain directions while reducing it in others.

When carbon fibers are exposed to high temperatures, they can oxidize and lose some of their most valuable properties. This degradation can happen slowly, over a period of years, or it can be much more rapid, in the case of an accident.

Lu’s team has developed an inexpensive and simple method of protecting carbon fibers against this type of damage. Their approach uses a molten salt coating, rather than more complex techniques such as chemical vapor deposition. Their test results were promising, suggesting that the new coating could be effective against both thermal and oxidation damage.