If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

Why is zinc stearate water-based emulsion used?

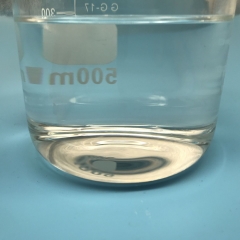

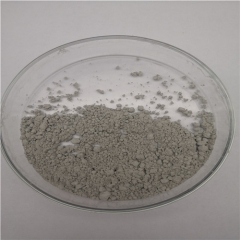

Aqueous zinc Stearate, also known as aqueous zinc-stearate, is an emulsion of Zinc Stearate.

Zinc Stearate Emulsion

This dispersion is white and has a slippery feel. Zinc Stearate Emulsion is easy to disperse, has a fine lubrication that can be sanded, and it dries quickly. It also defoams easily. It is a versatile product that can be used in a number of ways, such as a release agent or color retention agent. Material Co., Ltd. provides zinc stearate in emulsions with a solids level of 40%.

The release agent is now a crucial industrial raw-material in industrial production. It has played an important role in mold shaping and in improving the appearance and quality industrial products. Different release agents are needed for different mold materials.

Are there different types of common mold release agents available?

1. Use the Release Agent

There are different types of internal and external mold release agent. There is a large price difference between the materials used in the external and internal mold releases. The mold release can be applied directly with the external release agent. On the mold, an internal mold release is a chemical compound whose melting temperature is lower than normal molding temperatures. The internal mold releases agent is added to resin and mixed in with the resin before use. (Note : Compatible with liquid and solid resin.) Under certain conditions of processing temperature, it can seep through the resin matrix and form a thin, insulating film between the product and the mold, which provides a release.

2. Combination of release agent

Compound mold release and single mold releases. Compound mold releases include both compound and component components in their use. In some cases, composite and single mold releases can be quite expensive and perform well. difference;

3. The release agent’s temperature can be classified into

The release agents are classified as high temperature release agents and normal temperature release agents.

4. Reuse of release agents

Mold release agents are classified as semi-permanent or consumable, based on their service life.

5. Release agent performance

The chemical components of solvent-based, waterbased, and oilbased mold-release agents differ, leading to different properties. Emulsion of zinc stearate This is a water based mold releaser.

What is the application of zinc stearate Emulsion?

Zinc Stearate Emulsion is used for heat stabilizer, grease, and thickener. As an example, it is commonly used as a PVC resin heat stabilizer. It can be used for industrial transparent products. Can be used with non-toxic products.

1. Rubber industry uses release agents, active agents, and others.

2. Use of internal release agents in plastics

3. Applications in the coating industry include color retention agents, fillers, and sandpaper.

4 . Use in plastics, paint and the automotive industry: Grinding aid

5. Application in the cosmetics sector: lubricant

Which nanomaterials manufacturer can be trusted?

(aka. Technology Co. Ltd., a global chemical supplier and manufacturer with more than 12 years’ experience in the production of super-high-quality chemicals & Nanomaterials. Our company is currently developing a range of powder materials. Our OEM service is also available. If you’re looking for Emulsion of zinc stearate Please contact us. Please click on Needed products Send us an inquiry.

Are there different types of common mold release agents available?

1. Use the Release Agent

There are different types of internal and external mold release agent. There is a large price difference between the materials used in the external and internal mold releases. The mold release can be applied directly with the external release agent. On the mold, an internal mold release is a chemical compound whose melting temperature is lower than normal molding temperatures. The internal mold releases agent is added to resin and mixed in with the resin before use. (Note : Compatible with liquid and solid resin.) Under certain conditions of processing temperature, it can seep through the resin matrix and form a thin, insulating film between the product and the mold, which provides a release.

2. Combination of release agent

Compound mold release and single mold releases. Compound mold releases include both compound and component components in their use. In some cases, composite and single mold releases can be quite expensive and perform well. difference;

3. The release agent’s temperature can be classified into

The release agents are classified as high temperature release agents and normal temperature release agents.

4. Reuse of release agents

Mold release agents are classified as semi-permanent or consumable, based on their service life.

5. Release agent performance

The chemical components of solvent-based, waterbased, and oilbased mold-release agents differ, leading to different properties. Emulsion of zinc stearate This is a water based mold releaser.

What is the application of zinc stearate Emulsion?

Zinc Stearate Emulsion is used for heat stabilizer, grease, and thickener. As an example, it is commonly used as a PVC resin heat stabilizer. It can be used for industrial transparent products. Can be used with non-toxic products.

1. Rubber industry uses release agents, active agents, and others.

2. Use of internal release agents in plastics

3. Applications in the coating industry include color retention agents, fillers, and sandpaper.

4 . Use in plastics, paint and the automotive industry: Grinding aid

5. Application in the cosmetics sector: lubricant

Which nanomaterials manufacturer can be trusted?

(aka. Technology Co. Ltd., a global chemical supplier and manufacturer with more than 12 years’ experience in the production of super-high-quality chemicals & Nanomaterials. Our company is currently developing a range of powder materials. Our OEM service is also available. If you’re looking for Emulsion of zinc stearate Please contact us. Please click on Needed products Send us an inquiry.