If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

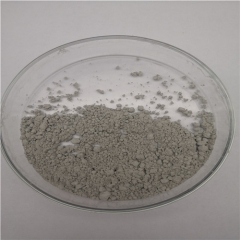

Magnesium fluoride (MgF2) is a white crystalline compound which can be found naturally as the rare mineral sellaite. It is a tetragonal crystal with high birefringence and it can be used to make windows, wedges and other optical components for polarizing mirrors and lenses to reduce the glare of sunlight on optical equipment. It also has a high transmittance in the vacuum ultraviolet region and can be used to protect sensitive optical coatings from laser damage. However, it is toxic and if swallowed can cause acute toxicity. It is also a skin, eye and respiratory tract irritant and can cause toxicity if inhaled. It is also very volatile and can explode at high temperatures.

The preparation of MgF2 is simple and cheap and it can be made by reacting any water-soluble magnesium salt such as the sulfate, chloride or nitrate with hydrofluoric acid. The reaction is carried out in a glass or ceramic vessel at a temperature between 200 and 300 degC and it is accelerated by stirring. The resulting magnesium fluoride is then calcined at 670 K in air.

Depending on the magnesium salt used, different porous structures of MgF2 are obtained. The most important differences are reflected by the shape of hysteresis loops for low-temperature nitrogen adsorption, specific surface area, pore size and pore volume. In particular, the MgF2 samples prepared by the carbonate and alumina methods showed significant differences in the porosity. The alumina-based sample had the greatest porosity, followed by the carbonate-based and then the spherical-shaped MgF2. All the samples were mesoporous with the mean pore diameter of 8 to 18 nm. A considerable influence of the MgO content on the basicity of the MgF2-MgO systems was also observed.