If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

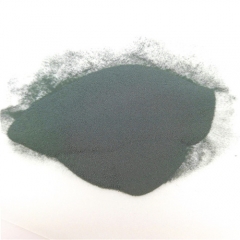

What are the properties of nitinol metallic powder?

Nitinol Metal Powder NiTi powder belongs to Shape Memory alloys (SMA, for short). This alloy has the ability to completely eliminate deformation when heated at a low temperature, and then restore it after further heating. The alloy material with “memory’ effect is the alloy in its original shape.Many successful applications of nitinol metallic powder have been made in the aerospace industry. Memory alloys can be used for the antenna on an artificial satellite. Fold the parabolic satellite antenna into the body of the artificial satellite before it is launched. It is only necessary to heat the satellite after the rocket launches to place it in a specific orbit. The “memory function” of the folded antenna allows it to unfold and restore its parabolic shape.

Shape memory alloys have many applications in aerospace, electronics and machinery, biomedicine, bridge building, automobile industry and everyday life.

What is nitinol metallic powder preparation?

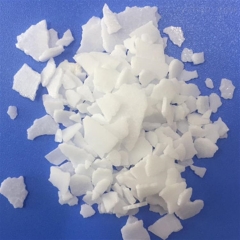

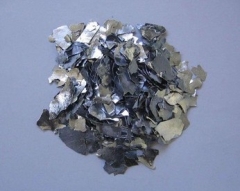

The following raw materials are used for the PREP process to produce spherical metal powders of nitinol: NiTi bars.Preparing spherical Nitinol Metal Powder by PREP Method is as follows: The raw materials must be weighed and sized according to the experimental plan and poured into the cemented carbide tank ball milling for wet grind. The ball milling period is 24 hours. After the ball-milling, the pellets are vacuum-dried, with a drying time of 50 min and a temperature of 38deg C. They are then added to the granulation agent as a formant. The powdered material is placed in a hydraulic single-column press to be compressed, then it is placed into an integrated dewaxing/low-pressure sintering furnace.

Tech Co., Ltd. () has over 12 year experience in chemical product development and research. You can find high quality Metal powder nitinol Feel free to contact us Contact us Send an inquiry.