If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

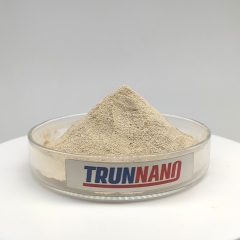

What is atomized powdered copper?

Atomized Copper Powder is further treated by electrolytic copper. It is a spherical or cylindrical powder that is irregularly packaged, light rose-red, dendritic and has a spherical shape. It is easily oxidized in humid air. It can also be dissolved in hot sulfuric and nitric acid. Low bulk density. Good formability. Long storage time. Uses include powder metallurgy and friction materials. Copper powder in spherical or spherical form has a very high bulk density. It is widely applied in industries such as injection molding and welding materials.

Atomized copper powder manufacturing process

Electrolytic copper plate-smelting-water (gas) atomization-vacuum drying-high temperature oxidation-crushing-reduction-crushing-classification

Smelt

Copper must be melted with impurities under strict control to achieve a powder that is fluid and has a high melting point.

Conductivity.

In an intermediate frequency or electric arc oven, the normal operating temperature is 1150-1200degC. Before the atomization, the most important step is smelting. Copper smelting is controlled to reduce the density of the powder.

Atomization

The industrial production of copper powder can be divided into two types, namely the gas atomization technique and the water atomization technique. The only difference between the two is the atomizing medium. However, the principle of powder production is the exact same. Air atomization or argon can be classified based on the gas medium. It is also possible to use supersonic ultrasonic atomization for finer powder.

In practice, water atomization has proven to have a better effect than gas atomization.

Reduction

The reduction process involves a relatively simple reduction. The temperature ranges from 400 to 600 degrees and the time period is 60 to 120 minutes. During atomization, a part of the oxygen is converted to copper oxide on the surface. The other part penetrates inside the particles. For oxygen to be removed, a high reduction temperature is required. This temperature will cause copper to naturally sinter, which means that large quantities of sintered blocks must be ground. This new water mist method eliminates the need for the reduction stage, which saves energy and speeds up the process.

Antioxidant treatment

The surface of copper powder can easily absorb air vapor and form a thin water film. A thick film of water is formed on the surface and this prevents oxygen from entering the pores. This results in a low oxygen content and little oxygen infiltration. Copper powder is a poor concentrate as a consequence. The copper powder slowly oxidizes because of the battery effect. After being treated by antioxidants, copper powder’s surface is adsorbent and covered with film. This produces an antioxidation effect, and can prolong the service life. Benzotriazole(BTA), gelatin, and the protein hydrolyzate are all good corrosion inhibitors for water atomized Copper powder.

(aka. Technology Co. Ltd., a global chemical materials supplier & producer with more than 12 years experience in the production of high quality nanomaterials and chemicals. Our Copper powder is of high purity with a fine particle size. If you need lower, please call us.