If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

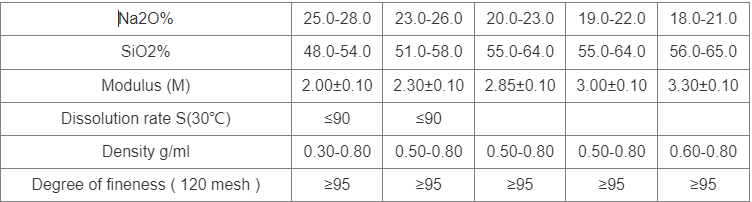

Technical Parameters of Powdered Immediate Sodium Silicate (CAS 1344-09-8)

(Technical Parameters of Powdered Instant Sodium Silicate (CAS 1344-09-8))

Keep in mind: We can also customize salt silicate powder with moduli of 2.45, 2.5, and 3.4 according to your needs.

Our Series Of Salt Silicate Moduli

We provide powdered immediate salt silicate with moduli ranging from 2.0 to 3.3. Furthermore, we can tailor salt silicate powder with moduli of 2.45, 2.5, and 3.4 to satisfy your certain demands.

Intro

In the middle of the rising international concentrate on environmental preservation and sustainable growth, salt silicate, a critical inorganic compound, is garnering increased focus across diverse industrial domain names. Also called water glass or soluble glass, sodium silicate is a versatile not natural substance. It not just plays an essential duty in the building and construction and paper markets yet is additionally a key component in cleaning agent manufacturing. In the last few years, typical phosphorus-containing detergent ingredients like sodium tripolyphosphate (STPP) have been phased out as a result of their severe contamination of water bodies. For this reason, journalism demand for reliable and eco-friendly choices has emerged. Against this backdrop, sodium silicate has acquired substantial attention because of its one-of-a-kind performance advantages.

Market Lead

1. Worldwide Demand

The global production of synthetic detergents is continually growing, with a boosting share of highly focused powders. It is approximated that a minimum of 230,000 tons of salt silicate were required in the year 2000 alone to meet market demand. Currently, the international production of sodium silicate is restricted, resulting in a considerable supply-demand space, which shows considerable development possibility. As worldwide consumers significantly require top quality living criteria, the requirement for environment-friendly cleaning agents will also increase, additionally driving the growth of the sodium silicate market.

2. International Competitiveness

Contrasted to most global equivalents, Chinese-produced salt silicate not just supplies a substantial rate benefit but likewise boasts superior high quality, making it very competitive for export. As an example, in the USA, the FOB rate for salt silicate is about $51.15 per 100 extra pounds, while costs in Europe are even higher; this makes Chinese-produced salt silicate highly affordable in the international market. With continual technical advancement and quality improvement, Chinese-produced salt silicate is positioned to catch a bigger share of the global market.

Review of Salt Silicate

Salt silicate is a substance formed from silicon dioxide (SiO ₂) and sodium oxide (Na ₂ O), normally represented by the formula Na ₂ O · nSiO ₂. Depending on the value of n, various kinds can be identified. Sodium silicate shows superb solubility, a high pH, and impressive cleaning buildings, making it an ideal cleaning agent additive. Past its use in detergents, salt silicate is commonly made use of in the building sector as a waterproofing material and sealer. In the paper sector, it improves the toughness and level of smoothness of paper. Furthermore, it locates applications in fabric dyeing, oil extraction, and various other fields.

Manufacturing Process of Salt Silicate

1. Basic Material Prep work: Usage water glass (or quartz sand) and caustic soda as base materials.

2. Dissolution Stage: Blending the raw products and warming them to a proper temperature level to advertise dissolution, guaranteeing all parts are completely mixed.

3. Crystallization Therapy: Controlling conditions to create details crystal structures, calling for specific guideline of temperature level and stress parameters.

4. Filtering and Splitting up: Using plate and structure filters to remove excess water and impurities, ensuring product purity.

5. Drying and Forming: Employing spray drying modern technology to lower the dampness web content additionally, ultimately developing a powdered final product, which is easy to store and transportation.

( sodium silicate)

Cost-Benefit Evaluation

1. Variable Costs: About $346.71 per lot, including raw materials (water glass/quartz sand + caustic soft drink), power consumption (electricity + gas), and labor costs.

2. Fixed Expenses: About $141,400 per year, covering depreciation and maintenance of set assets, management costs, interest on lendings, and other expenditures.

3. Overall Expenses: Considering all elements, the estimated price per ton of completed item is around $385.71.

4. Sales Revenue: With an estimated market price of 642.86 per bunch, the earnings margin has to do with 642.86 per heap, theprofitmarginisabout257.15 per heap.

5. Economic Advantages: The yearly output value can reach 3,214,300, contributingapproximately3,214,300 contributingapproximately1,285,700 in tax obligation profits.

Final thought

In recap, sodium silicate, with its remarkable technical efficiency and reduced production costs, demonstrates great possible in changing typical phosphorus-containing additives. Provided the tightening environmental guidelines and the rising consumer appetite for superior living standards, the research, growth, and commercialization of salt silicate will unquestionably work as an essential catalyst beforehand the global detergent market’s advancement. For capitalists, entering this field not just boosts the business’s social duty photo but likewise brings significant economic returns and social benefits. As technical innovations unravel and the market expands, the possible applications of salt silicate are comprehensive and quality detailed expedition and development by pertinent ventures and research study bodies.

Premium Sodium Silicate supplier

TRUNNANO is a supplier of Sodium Silicate Materials with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about sodium silicate solution suppliers, please feel free to contact us and send an inquiry(sales5@nanotrun.com).

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us