If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

Is tungsten carbide better than tungsten?

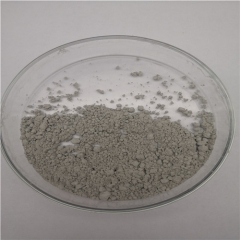

Tungsten carburide is a dense, grayish-blue metal that decomposes instead of melting at 2600degC. The powdered tungsten is heated with carbon black in hydrogen at temperatures between 1,400deg and 1,600degC (2.550deg-2.900degF).

Tungsten carburide is similar to tungsten in many ways, including its durability, strength, high melting point and other characteristics. However, it is an improved metal. Tungsten is Mohs 7.5. Tungsten carbide has a high scratch resistance of Mohs 8 to 9 and is used as the hardest metal in jewelry.

Does tungsten carbide have a higher strength than steel?

WC, when it is in its single carbide form (the chemical formula for WC), can rival diamond as the hardest known material. Its impact resistance, toughness and scratch/scratch/erosion resistance are excellent, and its service life under extreme conditions is 100 times that of steel.

Tungsten carbide is the hardest metal on earth. Tungsten-carbide jewelry is comparable to gold and platinum, and it is also lightweight and moderately priced. Tungsten’s hardness means it will not bend. This will prevent the ring from deforming unexpectedly, and causing further damage to your finger. The top tungsten carbide ring won’t lose its shine.

Why are tungsten carbide rings so cheap?

Because of the reduced amount of labor, tungsten ring prices are low. This will cause a drop in the level of precision and maintenance in ring production, which in turn will affect quality.

To test your ring, try to mark and apply it. If the ring resists marking it will be good. If it becomes dirty quickly and loses its luster in a matter of minutes, the quality is low.

The high hardness, durability and strength of tungsten carbide, as well as its high melting point, have many applications in our daily lives. There are many other benefits of tungsten carbide than just rings.

1. The tungsten carbide brake system has been changed by Porsche

The rotors coated with tungsten carbide will perform better, wear less, produce less brake dust, and have no rust.

The brake discs in most modern vehicles are made from carbon ceramic or cast iron. Porsche, however, has implemented a new brake disk made from tungsten carbide. This will revolutionize this industry.

The Porsche Surface Coated Brake, or PSCB is an iron brake rotor which has been coated with a layer superheated tungsten carbide at an extreme high speed. The result is a thick, dense coating of material with a 0.1-mm thickness. Porsche claims that despite the thinness of the useful materials, the rotor’s service life is 30 percent longer than that for an iron rotor.

Jason Fenske is also a contributor for Road and Track who said that the brake dust generated by PSCB was reduced by around 90% because the rotors wear very little during their lifetime. The tungsten carbide can also lower the temperature of the rotor after repeated hard braking.

2. EDC gear with tungsten carbide (hardness of 3.5 times titanium) will allow the entire service lifetime

The hardest metal known to mankind, titanium, is only 3.5 times as hard as tungsten. It’s like black gold for EDC. Any gear can be coated with a thin layer of tungsten carbide. It is black and shiny like obsidian. They are almost indestructible and resistant to external wear. Wingback’s Black Steel products are designed Alasdair macLaine, and they have three features that do not meet the minimum requirement. You will find them indispensable in your daily life. The bullet-sized cache key can help you to store emergency money in your keychain. The mechanical pen will be the last pen that you use.

MacLaine’s hip flask 100ml has the same cylindrical lathe design as all other products in this series. This hip flask is unique in its appearance and functionality, thanks to the innovative design. It can be used as a corkscrew and for storing liquids.

All Black Steel Products are manufactured by precision lathes made of stainless steel in the UK. A revolutionary process known as magnetron spraying is then used to coat a magical tungsten-carbide surface with 3um. Due to the steel structure underneath the black coating, the black material still retains a high gloss. You can laser engrave personalized and customized inscriptions onto your products, revealing shiny steel underneath the black coating.