If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

Tungsten Powder Properties

The hardness is highest among all metals. The hardness ranges from 200-250 for sintered rods, and 350-400 when tungsten is passed through the rotary hammer. Tungsten is dissolved in an acid mixture of nitric and hydrofluoric acids and then melted using a sodium hydroxide-sodium carbonate mixture.Tungsten is a grayish-black metal that has a metallic sheen (cubic crystals with a center of the body). Tungsten powder has a slight solubility in nitric, sulfuric, and aqua regia acids; however, it is not soluble in water.

Tungsten Powder Preparation

Tungsten is produced by hydrogen reduction. The preparation of tungsten powder using the hydrogen reduction method can be divided into two steps: in the first step, at 500-700°C, tungsten dioxide is converted to tungsten oxide; the second at 700-900°C, or at the temperature 700900°C. The reduction of tungsten to powder is carried out. The reduction reaction takes place in an electric tube or rotary furnace.The properties of reduced powder (such purity, particle sizes, particle size composition etc.) depend mainly on the reduction process. The main factor is the reduction process. In a tube oven, when reducing the tungsten, the main process variables that influence the rate of reduction are the reduction temperatures, the loading of the tungsten oxide into the burning boat and its speed, as well as the flow rate of the hydrogen. As the temperature of reduction increases, the particle sizes of the tungsten become coarser.

This method is used in addition to the hydrogen-reduction method. This method yields a relatively low-purity tungsten powder. In addition, work is being done on the reduction tungsten with metals such as aluminum, calcium, and zinc. Research is also underway. This method can produce ultra-fine tungsten particles with a particle size less than 0.05mm.

Tunsten Powder Applications

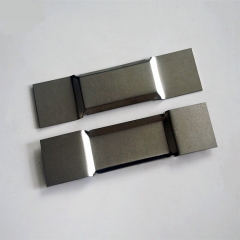

Tungsten is used mainly in the productions of ferro tungsten and cemented carbide. The alloy of Tungsten Powder, Chromium, Molybdenum and Cobalt is heat-resistant, wear-resistant, and used for gas turbine blades, combustion tubes and tooling. Tungsten, tantalum, molybdenum and niobium powders, for example, form a heat-resistant alloy. This alloy is refractory.High-density tungsten-nickel-copper alloy is used as a radiation shield. Metal tungsten wires, rods, sheets, etc. These are used for the production of electronic tubes, light bulbs and electrodes for welding. Tungsten can be sintered to create filters of various porosities.

Tungsten Powder is the main raw materials for powder metallurgy and alloy tungstens. Pure tungsten is processed into materials like wires and rods. It can also be made into tubes, plates, plates with specific shapes, and other products. Tungsten powder can be mixed with other metals to create various alloys. These include tungsten and copper alloys, tungsten and molybdenum, tungsten and rhenium, as well as high-density, tungsten. A tungsten-carbide powder is another important use of the powder. This powder can be used to produce cemented carbide products such as turning tools and milling cutters.

Tech Co., Ltd. is a professional tungsten powder With over 12 year experience in chemical product research and development. We accept payment by Credit Card, T/T (West Union), Paypal, West Union or T/T. The goods will be shipped to overseas customers via FedEx or DHL.

You can contact us for high-quality tungsten if you want to. Contact us Send an inquiry.