If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

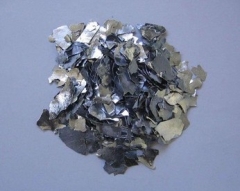

tungsten titanium alloy is a high strength, lightweight alloy that has exceptional resistance to oxidation and corrosion. It is an excellent choice for highly stressed components. It is often used in aircraft, spacecraft, bicycles, medical devices and jewelry.

Several tungsten titanium alloys can be produced in different proportions of tungsten and titanium. A typical tungsten titanium alloy consists of 90-97% tungsten, with the remainder being a matrix of other metals to improve the ductility and machinability of the alloy.

The refractory nature of W makes it difficult to produce homogenous Ti alloys with W as the binder. The melting point of W is 3,422 deg C and its density is 19.3 gms/cm3.

As a result, remelting the ingot several times is required to obtain a homogenous alloy. This process can be performed in an automatic remelting machine or manually by hot working.

In addition, the refractory nature of W may prevent a homogenous alloy from being formed in the heat treatment phase. To avoid this problem, a refractory metal such as aluminum can be added to the alloy to increase its ductility.

tungsten titanium alloys are available in powder, bars, ribbons, wires, sheets, sputtering targets and foils. AE Alloys also offers custom alloys in a wide variety of element compositions. Contact us today to discuss your specific application. Our experienced engineering staff will help you select the right alloy to meet your needs.