If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

Metal 3D Printing is a 3D technology that uses metal powders to directly print metal parts. This technology is also called Selective Laser Melting. 3D printed metal powders need to have good plasticity.

Metal powders are used in 3D printers for stainless steel, aluminum, cobalt chromium alloys, copper alloys, titanium alloys, and nickel alloys. Iron base alloy is the largest and most important metal material in engineering technology. It is widely used for the creation of complex structures.

The performance of the final product will depend on the type of metal powder and 3D printing method used.

Stainless-steel powder

Low-cost metal printing materials can be used for small batches of complex industrial parts manufacturing.

Aluminium alloy powder

AlSi12Mg is the most commonly used aluminum alloy in metal 3D printers. Aluminosilicate 12 (lightweight additive) is used to create metal powders with excellent thermal properties. Combining silicon and magnesium gives aluminum alloys greater strength and stiffness. They are suitable for thin walls, complex geometry, and applications with high thermal properties. Aluminum alloy is an industry staple due to its low density, high specific strengths, close to or greater than high-quality steel and good plasticity. 3D printing of aluminum alloy has been shown to produce compact parts with small structures, similar to casting, or even better than cast molding parts. The cost of 3D printing can be cut by as much as 30% compared to traditional process parts.

Cobalt chrome alloy powder

It is well-suited for printing all kinds of artificial joints, plastic surgery implants and other dental procedures due to its wear resistance and resistance to corrosion.

Copper alloy Powder

Copper has excellent thermal conductivity as well as electrical conductivity. It can be used in thermal management applications to combine design degrees for complex internal structures and conformal cool channels.

Titanium alloy powder

It is widely used within the aerospace industry. 3D printing offers many benefits. One example is the ability to replace a solid body with a complex, reasonable structure. The result is a product that is lighter and has better mechanical properties. This will not only reduce costs but also allow for lighter production.

Nickel alloy pulver

Nickel alloy’s oxidation and corrosion resistance make it ideal for harsh environments such as high temperatures and high levels of pressure. To protect the internal nickel alloy from corrosion, the nickel alloy’s surface will undergo heat passivation. Nickel alloys have good mechanical properties across a wide range temperature ranges.

Can powdered materials be used in 3D printing?

3D data can be used to control laser beams of high energy to melt metal matrix locally and then sinter it to form solidified parts.

How do you make 3D printing metal powder?

Solid-state reduction, electrolysis and chemical are the most common methods to produce metal powders.

Many manufacturers use electrolysis or reduction methods to make elemental metal particles. However, they are not suitable in making alloy powders.

Alloy powder can be made using the atomization method.

Another way to make powdered metals is by electrolysis. Different metals can either be made spongy, or powdered by selecting the right electrolyte composition and temperature, concentration, as well as current density. These can then be washed or dried and reduced to a powdered form. This process is used to make extremely pure metal powder. This method is used to make highly conductive copper powder.

The mechanical method of pulverizing the molten steel into small particles less than 150mm is known as the Atomization Method. According to the classification for crushing metal melt, the atomization process includes the second flow, centrifugal and ultrasonic atomizations, as well as vacuum atomization. Each of these atomization techniques has their own unique characteristics, and they have been used successfully in industrial production. Water-gas atomization is one of the most preferred industrial methods for making metal powder. It has simple equipment and processes, as well as low energy consumption.

Performance requirements of metal powder for 3D printing

1. Purity

Ceramic inclusions can adversely affect the performance of final products. They also have a high melting points, which makes it difficult to sinter. Powders must not contain ceramic inclusions. You must also control the nitrogen and oxygen levels. Powder preparation is done mainly using the atomization method. The powder is easily oxidized due to its large surface area. This index is required by customers for special applications such as aerospace. The superalloy and titanium alloy powder oxygen contents are 0.006% to0.018% and 0.007% to0.013% respectively. The oxygen content of stainless steel powder is 0.010%–0.025%.

2. Powder fluidity, loose density

The powder’s fluidity directly influences the uniformity of powder spreading as well as the stability of powder feeding. Powder morphology, bulk density and particle size distribution are all factors that affect the fluidity. Fluidity is dependent on the size and distribution of powder particles. A larger proportion of fine powders in the particle size composition will result in a more consistent shape. Fluidity of powder increases as a function of particle density and relative density. The fluidity of powder is also reduced by the adsorption gas and water on its surface.

3. Powder particle size distribution

Different 3D printing equipments and forming processes have different requirements for powder size distribution. The most commonly used powder particle size range in metal 3D printing at the moment is between 15-53mm (fine) and 53-105mm (“coarse”). There are several energy sources that can be used to select the metal powder size for 3D printing. Because of the fine focal spot and ease of melting fine powder, printers using laser energy are ideal for 15-53mm. A powder-laying printer that uses electron beam as an energy source has a slightly larger focal spot which makes it more suitable to melt coarse powder. It can be used for coarse powders of 53 to 105mm. As consumables for coaxial powder feeders, powders with particle sizes between 105 to 150mm are possible.

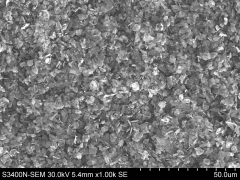

4. Powder morphology

The powder preparation method has a direct impact on the morphology. Powder particles that are made from molten metal liquid or metal gas tend to be spherical. But powder particles made by aqueous electrolysis have a more irregular shape. Generally speaking, higher sphericity means better fluidity for powder particles. This makes it easier to feed and lay powder during 3D printing.

3D printing metal powder supplier

Technology Co. Ltd. is a trusted global supplier and manufacturer of chemical materials. We have more than 12 years experience in producing super high-quality chemicals.

Send us an inquiry if you’re looking for high-quality 3D printing metal powder. (brad@ihpa.net)

Metal powders are used in 3D printers for stainless steel, aluminum, cobalt chromium alloys, copper alloys, titanium alloys, and nickel alloys. Iron base alloy is the largest and most important metal material in engineering technology. It is widely used for the creation of complex structures.

The performance of the final product will depend on the type of metal powder and 3D printing method used.

Stainless-steel powder

Low-cost metal printing materials can be used for small batches of complex industrial parts manufacturing.

Aluminium alloy powder

AlSi12Mg is the most commonly used aluminum alloy in metal 3D printers. Aluminosilicate 12 (lightweight additive) is used to create metal powders with excellent thermal properties. Combining silicon and magnesium gives aluminum alloys greater strength and stiffness. They are suitable for thin walls, complex geometry, and applications with high thermal properties. Aluminum alloy is an industry staple due to its low density, high specific strengths, close to or greater than high-quality steel and good plasticity. 3D printing of aluminum alloy has been shown to produce compact parts with small structures, similar to casting, or even better than cast molding parts. The cost of 3D printing can be cut by as much as 30% compared to traditional process parts.

Cobalt chrome alloy powder

It is well-suited for printing all kinds of artificial joints, plastic surgery implants and other dental procedures due to its wear resistance and resistance to corrosion.

Copper alloy Powder

Copper has excellent thermal conductivity as well as electrical conductivity. It can be used in thermal management applications to combine design degrees for complex internal structures and conformal cool channels.

Titanium alloy powder

It is widely used within the aerospace industry. 3D printing offers many benefits. One example is the ability to replace a solid body with a complex, reasonable structure. The result is a product that is lighter and has better mechanical properties. This will not only reduce costs but also allow for lighter production.

Nickel alloy pulver

Nickel alloy’s oxidation and corrosion resistance make it ideal for harsh environments such as high temperatures and high levels of pressure. To protect the internal nickel alloy from corrosion, the nickel alloy’s surface will undergo heat passivation. Nickel alloys have good mechanical properties across a wide range temperature ranges.

Can powdered materials be used in 3D printing?

3D data can be used to control laser beams of high energy to melt metal matrix locally and then sinter it to form solidified parts.

How do you make 3D printing metal powder?

Solid-state reduction, electrolysis and chemical are the most common methods to produce metal powders.

Many manufacturers use electrolysis or reduction methods to make elemental metal particles. However, they are not suitable in making alloy powders.

Alloy powder can be made using the atomization method.

Another way to make powdered metals is by electrolysis. Different metals can either be made spongy, or powdered by selecting the right electrolyte composition and temperature, concentration, as well as current density. These can then be washed or dried and reduced to a powdered form. This process is used to make extremely pure metal powder. This method is used to make highly conductive copper powder.

The mechanical method of pulverizing the molten steel into small particles less than 150mm is known as the Atomization Method. According to the classification for crushing metal melt, the atomization process includes the second flow, centrifugal and ultrasonic atomizations, as well as vacuum atomization. Each of these atomization techniques has their own unique characteristics, and they have been used successfully in industrial production. Water-gas atomization is one of the most preferred industrial methods for making metal powder. It has simple equipment and processes, as well as low energy consumption.

Performance requirements of metal powder for 3D printing

1. Purity

Ceramic inclusions can adversely affect the performance of final products. They also have a high melting points, which makes it difficult to sinter. Powders must not contain ceramic inclusions. You must also control the nitrogen and oxygen levels. Powder preparation is done mainly using the atomization method. The powder is easily oxidized due to its large surface area. This index is required by customers for special applications such as aerospace. The superalloy and titanium alloy powder oxygen contents are 0.006% to0.018% and 0.007% to0.013% respectively. The oxygen content of stainless steel powder is 0.010%–0.025%.

2. Powder fluidity, loose density

The powder’s fluidity directly influences the uniformity of powder spreading as well as the stability of powder feeding. Powder morphology, bulk density and particle size distribution are all factors that affect the fluidity. Fluidity is dependent on the size and distribution of powder particles. A larger proportion of fine powders in the particle size composition will result in a more consistent shape. Fluidity of powder increases as a function of particle density and relative density. The fluidity of powder is also reduced by the adsorption gas and water on its surface.

3. Powder particle size distribution

Different 3D printing equipments and forming processes have different requirements for powder size distribution. The most commonly used powder particle size range in metal 3D printing at the moment is between 15-53mm (fine) and 53-105mm (“coarse”). There are several energy sources that can be used to select the metal powder size for 3D printing. Because of the fine focal spot and ease of melting fine powder, printers using laser energy are ideal for 15-53mm. A powder-laying printer that uses electron beam as an energy source has a slightly larger focal spot which makes it more suitable to melt coarse powder. It can be used for coarse powders of 53 to 105mm. As consumables for coaxial powder feeders, powders with particle sizes between 105 to 150mm are possible.

4. Powder morphology

The powder preparation method has a direct impact on the morphology. Powder particles that are made from molten metal liquid or metal gas tend to be spherical. But powder particles made by aqueous electrolysis have a more irregular shape. Generally speaking, higher sphericity means better fluidity for powder particles. This makes it easier to feed and lay powder during 3D printing.

3D printing metal powder supplier

Technology Co. Ltd. is a trusted global supplier and manufacturer of chemical materials. We have more than 12 years experience in producing super high-quality chemicals.

Send us an inquiry if you’re looking for high-quality 3D printing metal powder. (brad@ihpa.net)