If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

Aluminum oxide, also known as aluminum oxide, is a white solid, which is not soluble in any liquid, has no taste or odor, and it’s extremely hard. It is a white solid that absorbs water easily, but it doesn’t deliquescence. Aluminum oxide is amphoteric oxide, which is easy to absorb moisture but does not deliquescence (after burning, it will not absorb moisture). It is inert, corrosion resistant, slightly soluble, alkaline, and inorganic acid solutions.

Application of nano Aluminum oxide

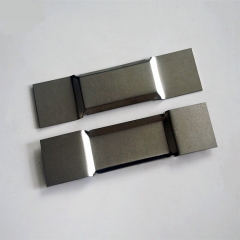

Lithium separator coating material

The high-purity Nano-Aluminum dioxide is used to coat the positive and the negative electrode separators. It has a heat-resistant, high-temperature-resistant, and insulation function, which prevents the battery from overheating due to temperature. The battery is melted and short-circuited.

Lithium cathode materials additives

High-purity Nano-Aluminum doped by lithium cobalt, lithium manganate etc. Improve thermal stability, cycle performance, overcharge resistance and inhibit oxygen generation. Reduce the electrochemical loss of specific capacity, increasing the specific capacity LiCoO2.

Catalyst Carrier:

High-purity g-type Nano- Aluminum oxide This porous material has a surface area per gram of hundreds of square metres, high activity and a strong adsorption ability. It is widely used in the petroleum refinery and petrochemical industries as an adsorbent. Its drying ability is comparable to that of phosphorus hexoxide. After usage, it can also be regenerated by heating to 175degC and using for 6-8 hours.

Powder coatings that are resistant to caking

Powder coatings are made with nano aluminum oxide, which has an anti-caking and bulking effect. Nano-Aluminum can be used to prevent powder from agglomerating during summer. It also has excellent storage properties, especially for powders in environments with high temperature and humidity.

Wear-resistant Hardener for Coatings, Rubber, and Plastics

By adding Nano-Aluminum, oxide to the prepared coating, it can significantly improve the scratch-resistance and wear-resistance, which is up to five times better than the traditional coatings. Nano-Aluminum dioxide can be added to paints in order to form a uniform, very hard, fine network structure on the surface. This will protect the polymer paint below the layer from damage. Nano paint has a better anti-scratch than the original. Its performance is 3 times higher and is widely used for automobile paints. Adding nano aluminum oxide to the coating can increase its hardness by a significant amount. A 20% addition can bring the coating up to 6-7H. The coating’s transparency is not affected.

Thermoconductivity of adhesives, coatings, rubbers and plastics

Nano-scale Aluminum Oxide has a high thermal conduction and has a large amount spherical filling. Surface treatment agents like coupling agents can be used to improve the compatibility between the resin and filler as well as the thermal properties of the matrix without reducing the mechanical properties.

Ceramics:

Nano Aluminum oxide is high in purity, has uniform particle sizes, and is easily dispersed. Addition of VKL30 at a rate of 10% to sintered ceramics increases the molding pressure. It also reduces the number of pores. This results in a higher density ceramic green body.

Powder metals:

Nano Aluminum for metallurgy. Small particle size, large specific area, high activity. Adding 1-3% Nano Aluminum to the mix will prevent matrix densification, crystal grain enlargement, increased hardness and conductivity. Mechanical properties and melting point are also improved.

Polishing:

Aluminum oxide particles are uniform and have a high-spherical profile. It is also a great material for metallographic polishing. It is suitable for a variety of applications including stainless steel mirror, titanium, cast-iron, aluminum mirror, stone mirror, paint polishing and resin polishing.

(aka. Technology Co. Ltd., a global leader in chemical material manufacturing and supply with over 12 year’s experience, is a trusted supplier of high-quality nanomaterials. Boron Powder produced by our company is of high purity and has a low impurity level. Please. Contact us if necessary.