If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

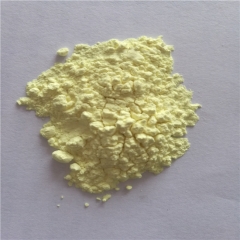

What is Nano Aluminum Nickel Powder?

Aerosol ablation produces nano aluminum nitride, also known as AlN. It is extremely pure, has a small particle size, and exhibits high surface activity. The powder obtained by surface modification is not subject to hydrolysis, and it has very low oxygen levels. It is easy to see the impact of insulation and thermal conductivity (0.01%). The viscosity increases are not evident when it is used in polymer resins. It is the best high-thermal conductivity insulating filler. A nano-aluminum-nitride is a nitride with diamond-like properties. It can be stable to 2200 at room temperatures and decreases with increasing temperature. It is resistant to heat shock and anti-melting. This makes it an excellent crucible material for casting pure aluminum, aluminum alloy, and pure iron. Nano-aluminum is also compatible with semiconductor silicon, making it ideal for compounding.

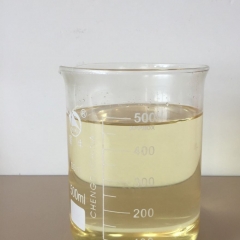

1. Nano lubricating and anti-wear oil: The modified nano aluminium nitride ceramics added to the nano ceramic oils act on the friction pair of the engine. To repair damaged surfaces, it is embedded in the dents and micropores of the metal to form a nanoceramic protective coating. The layer of protective film acts as an isolation layer, so the friction created by relative movement of parts acts only on that layer. Additionally, nano-ceramic particle, similar to small balls, transforms part of friction between friction pairs to roll friction. This reduces friction and reduces friction between moving parts. It also protects the engine from wear. You can reduce the friction coefficient by up to 80% and increase the anti-wear performance by more then 350% by improving your lubrication. You can reduce wear and tear by up to 80%, increase life expectancy by more the three-fold, reduce downtime, improve maintenance costs, prolong overhaul period by more over twice, save energy by 10-30%, and increase your equipment’s output power by 20%-40%. It takes only two thousandths to one millionths.

2. High thermal conductivity plastics can be used with modified nano aluminum Nitride powder. This powder can dramatically increase the thermal conductivity. Add 10-30% of the experiment product to the plastic and the plastic’s thermal conductivity will increase from 0.3 to 3. The plastic’s thermal conductivity also increases by more than 10x. This material is used primarily in PVC plastics and polyurethane plastics. ;

3. Other fields of application: Nano-aluminum is also used in crucibles that are used for smelting nonferrous metals or semiconductor materials GaAs.

Tech Co., Ltd. is a professional supplier boride powder. We have over 12 years of experience in chemical product development and research. We accept credit cards, T/T and Paypal payments. We will ship goods overseas via FedEx, DHL and by air or sea to our customers.

You can find high quality Aluminum Nitride powder here Get in touch Send an inquiry