If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

The aqueous emulsion zinc stearate has been called Zinc Stearate Emulsion . It can be used in a number of ways, such as as a release agent or color retention agent.

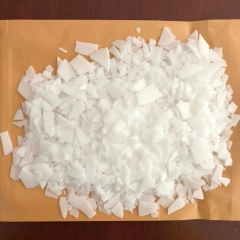

Z Inc stearate Characteristics

It is insoluble in water and soluble only in hot organic solvents, such as benzene or toluene. When exposed to acids, the stearic salts are formed.

Z Inc stearate Preparation

The water method or the melting method is the two main methods for producing zinc stearate.

The melting method produces zinc stearate that is generally alkaline, while the water method produces acidic zinc stearate. The water method can also be called the wet technique. The water is used as a medium. A catalyst is then added to control temperature and pressure. The metal ions will be replaced by the catalyst through the catalyst and then by the actual catalyst into stearin. Acid is added to the solution in order to generate metal salts. The catalyst goes through post-processing, and it is recycled. The stearate must be centrifuged, then dried and ground until it reaches a mesh size of 200-600. This product meets industry standards. In water production, there is usually a small excess of stearic acetic acid. This makes the final product appear acidic.

The dry method also known as the melting method is where the metal oxide is added directly to the molten acid. (Of course, this is done with a catalyst otherwise, the reaction rate will be extremely slow.) You can control the temperature, the pressure, and the stirring speed in order to get stearate. Dry method products can be fully reacted because of the presence and general results of a catalyst. Also, metal oxides in the product are slightly over-excessive, so it is alkaline.

Use of Zinc Stearate Emulsion

Zinc Stearate can also be used as an accelerator, thickener or lubricant. As an example, zinc stearate can be used in general as a heat stabiliser for PVC. Useful in transparent products for industrial use; when combined with a soap containing calcium, it can be used as a non-toxic product. Generally, this product has been used primarily in soft products. However, in recent years hard, transparent products like mineral water bottles and water pipes have also been used. This product can be used because it has a high level of lubricity. It is a product that can improve the look of fouling and also act as a lubricant.

Zinc stearate is widely used in rubber, plastics coatings paints thermal paper cosmetics and other industries.

Rubber Industry: release agents, release agents and active agents

Plastic industry: internal release agents

Coating industry: color retention agent, filler, etc.

Paint industry: grinding aids

Cosmetics industry: Lubricants

(aka. Technology Co. Ltd., a global leader in chemical material manufacturing and supply with over 12 year’s experience, is a trusted supplier of super-high-quality chemicals. Our Zinc Stearate Emulsion is of high purity with fine particles and low impurity. Please. Contact Us if necessary.