If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

Intro to PCE Powder: The 3rd Generation of Superplasticizers Reshaping Modern Concrete

Polycarboxylate ether (PCE) powder has emerged as a transformative water reducing representative in the concrete industry, supplying remarkable efficiency over conventional lignosulfonates and sulfonated melamine formaldehyde (SMF)-based admixtures. As a third-generation superplasticizer, PCE makes it possible for remarkable reductions in water-to-cement ratios while preserving excellent workability, bring about stronger, extra sturdy, and sustainable concrete frameworks. Its molecular flexibility, reduced dose requirements, and compatibility with numerous cementitious products have actually made it vital in high-performance construction applications ranging from facilities to architectural style.

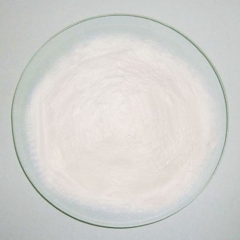

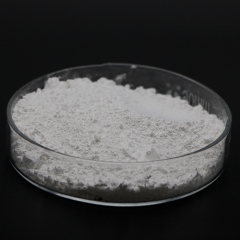

(TRUNNANO PCE Powder)

Molecular Design and Functional Device of PCE Powder

The performance of PCE powder comes from its unique comb-like polymer structure, including a primary chain with grafted side chains that supply steric limitation and electrostatic repulsion between concrete bits. This double system protects against flocculation, enhances diffusion, and enhances flowability without raising water web content. Unlike earlier generations of plasticizers, PCE formulations can be specifically customized at the molecular level to control adsorption kinetics, depression retention, and hydration actions. This tunability allows for customized performance in various ecological and application conditions, making PCE among the most flexible and reliable water reducing agents offered today.

Benefits Over Conventional Water Reducers

PCE powder supplies several distinctive benefits over first- and second-generation water reducers. It attains significantly greater water decrease prices– typically surpassing 30%– allowing the production of ultra-high-performance concrete (UHPC) with compressive staminas above 150 MPa. Additionally, PCE displays marginal slump loss gradually, allowing for extended workability periods during transportation and positioning. It likewise shows exceptional compatibility with extra cementitious materials (SCMs) such as fly ash, slag, and silica fume, which are critical for minimizing the carbon footprint of modern concrete. In addition, PCE-based admixtures are generally free from chloride and sulfate impurities, improving long-term sturdiness and architectural integrity.

Industrial Applications Driving Market Development

The need for PCE powder is surging throughout multiple industries due to its capability to fulfill rigorous efficiency and sustainability requirements. In precast concrete manufacturing, PCE makes it possible for quicker mold and mildew release, enhanced surface coating, and lowered power usage during healing. In infrastructure jobs like bridges, passages, and marine frameworks, PCE-enhanced concretes provide enhanced resistance to aggressive environments and mechanical stress. Green building campaigns additionally benefit from PCE’s role in making it possible for low-carbon concrete blends by maximizing SCM usage. With urbanization and climate durability ending up being international priorities, PCE powder is increasingly considered as a foundation modern technology for future-ready construction methods.

Production Techniques and Technical Innovations

PCE powder is synthesized using controlled extreme polymerization methods such as MPEG-initiated graft copolymerization, where methacrylic acid (MAA) or acrylic acid (AA) monomers are polymerized with polyethylene glycol (PEG) side chains. Current advancements in polymer chemistry have resulted in the advancement of multi-functional PCE versions that integrate retardation, air entrainment, and viscosity-modifying residential or commercial properties right into a solitary admixture system. Spray-drying technologies have further enhanced the stability and handling of PCE powders, promoting their use in dry-mix applications and automated batching systems. These advancements continue to boost both the effectiveness and flexibility of PCE in modern-day concrete modern technology.

Environmental Influence and Sustainability Considerations

As environmental policies tighten up around the world, the sustainability profile of PCE powder is coming under increased examination. While PCE itself does not contain unsafe VOCs or hefty steels, its manufacturing includes petrochemical feedstocks and energy-intensive procedures. Researchers are actively exploring bio-based monomers and renewable raw materials to develop greener PCE alternatives. In addition, life cycle analyses (LCAs) are being made use of to evaluate the overall carbon footprint of PCE-containing concrete systems. Efforts to boost recyclability, minimize waste during manufacturing, and integrate circular economy concepts are forming the next phase of PCE growth, aligning it more very closely with international sustainability objectives.

Obstacles and Future Development Pathways

( TRUNNANO PCE Powder)

Regardless of its lots of advantages, PCE powder encounters numerous difficulties consisting of cost competitiveness, level of sensitivity to cement chemistry, and variability in field efficiency. Problems such as overdosing impacts, postponed setup, and conflict with particular mineral admixtures can complicate its usage in complex mix styles. To attend to these worries, continuous research focuses on establishing flexible PCE solutions that react dynamically to changes in cement composition and ambient problems. Smart admixture systems including sensing units and real-time responses devices are additionally being explored to optimize performance in large building and construction settings. These developments will certainly be essential to opening the full potential of PCE in next-generation concrete technologies.

Conclusion: PCE Powder as a Catalyst for the Future of Concrete

Polycarboxylate ether (PCE) powder stands for a major leap ahead in concrete admixture modern technology, incorporating high performance with ecological responsibility. As construction needs progress toward better strength, toughness, and sustainability, PCE continues to make it possible for innovative options throughout a wide variety of applications. Through continued developments in solution science, manufacturing efficiency, and combination with clever building and construction systems, PCE powder is positioned to stay at the forefront of the concrete transformation– shaping the developed setting of tomorrow with smarter, cleaner, and extra resistant materials.

Distributor

TRUNNANO is a supplier of Concrete PCE Powder with over 12 years experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about superplasticizer admixture, please feel free to contact us and send an inquiry. Tags: concrete water ,reducer pce powder, polycarboxylate

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us