If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

Advancements in Spherical Niobium Powder: Driving Technology and Sustainability Across High-Tech Industries

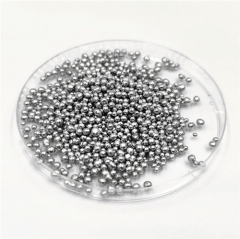

Spherical niobium powder stands as a testimony to the ongoing advancements in material science, playing a progressively essential duty in modern markets. Niobium, understood for its high melting factor, low thickness, and superb deterioration resistance, discovers itself transformed right into a versatile spherical powder type that offers unequaled benefits. This type of powder is produced making use of innovative techniques like gas atomization or plasma spheroidization, guaranteeing bits are perfectly rounded with consistent size distribution. Such attributes substantially enhance flowability and packing thickness, which are vital aspects for applications in additive production and steel shot molding. The one-of-a-kind residential properties of round niobium powder enable it to endure extreme environments, making it indispensable in aerospace elements, superconducting magnets, and other high-performance materials. In addition, this powder’s ability to conduct electricity and warm efficiently, along with its compatibility with human tissue, opens brand-new opportunities in electronics and clinical gadgets. As r & d efforts remain to uncover unique applications, round niobium powder is set to play an essential role in shaping the future of innovation and industry.

(Spherical Niobium Powder)

The production process of round niobium powder is a wonder of design accuracy and technology. Manufacturers leverage cutting-edge modern technologies to create powders that fulfill the strict demands of various markets. Gas atomization involves spraying molten niobium through a nozzle right into a chamber where it strengthens into spherical droplets upon call with a cooling medium. Conversely, plasma spheroidization utilizes high-energy plasma to thaw angular niobium powders, which after that cool down rapidly into balls. Both methods lead to powders that exhibit marginal porosity and remarkable mechanical homes compared to their irregularly designed equivalents. The enhanced flowability and consistency of spherical niobium powder make it especially ideal for 3D printing, where it can be made use of to produce complicated geometries with exceptional stamina and toughness. Past additive manufacturing, this powder functions as an essential component in the manufacturing of superalloys, adding to improved efficiency in jet engines and commercial generators. In the realm of electronic devices, the powder’s conductivity and thermal stability support the advancement of a lot more reliable capacitors and resistors. Clinical applications gain from niobium’s biocompatibility, bring about the production of implants that reduce the danger of being rejected by the body. With each passing day, the prospective applications for round niobium powder broaden, driven by the unrelenting quest of development across several sectors.

As the demand for high-performance products expands, so too does the market for round niobium powder. Industries such as aerospace, automobile, and electronic devices are progressively reliant on this powder to satisfy the difficulties of miniaturization, performance, and sustainability. Aerospace suppliers utilize niobium-based alloys for parts that must sustain extreme temperature levels and stress, guaranteeing trustworthy operation precede goals and industrial flights. Automotive companies check out the use of spherical niobium powder in electrical lorries, leveraging its light-weight residential or commercial properties to improve fuel efficiency and prolong driving array. Electronic devices suppliers value the powder for its function in creating compact and sturdy digital devices with the ability of operating under varied conditions. In addition, the clinical field maximize niobium’s biocompatibility to create innovative remedies for individual care. Ecological considerations also favor the adoption of round niobium powder, as niobium mining methods are usually much more lasting than those of some different metals. Recycling campaigns better advertise a round economic climate by recouping and reusing niobium from end-of-life products. As awareness of these benefits spreads, investment in spherical niobium powder is likely to boost, fostering technological development and increasing its energy in a globe increasingly focused on innovative materials and lasting techniques. The ongoing evolution of round niobium powder assures to unlock new possibilities for advancement across a large selection of industries.

TRUNNANO is a supplier of nano materials with over 12 years experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about Spherical Niobium Powder, please feel free to contact us and send an inquiry.(sales5@nanotrun.com)

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us