If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

Plastic

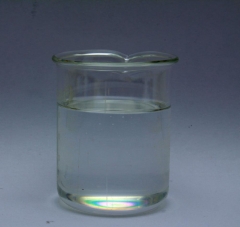

Nano-silica Light-transmissive with a smaller particle size. This can make plastics dense. When silica is added to polystyrene, it improves the film’s transparency, strength and toughness, as well as its waterproofing and anti-aging capabilities.

Rubber

Rubber is an excellent elastomer that has good stretch, but its overall performance isn’t satisfactory. Carbon black is added to rubber to improve its strength, wear resistance, aging resistance, and durability. Carbon black is added to rubber, but this results in a black product. The grade of the product is low. In China, nano-SiO2 is a material that has been used to produce a new generation rubber products. These products have novel colors and are of excellent performance.

When rubber is treated with nano-SiO2, its abrasion and flexural strength, as well as its resistance to aging, are improved. Its color also looks brighter, and color retention is better.

Organic dyes may have vibrant colors and strong tinting powers, but they are not as resistant to light, heat, solvents, or migration than inorganics. Addition of nano-SiO2 to organic dyes improves their anti-aging and brightness properties.

Ceramics

Using nano-SiO2 Instead of adding traditional Nano-additives to ceramics, the particles can be added in two phases. This not only increases the toughness and strength of the ceramic but also its hardness and modulus. The performance is better and the effect is more optimal than traditional Nano

additives.

By using nano-SiO2 in the composite of ceramic substrates, not only is the density, toughness and smoothness improved, but the sintering temp greatly reduced. The application of nano-SiO2 to ceramic products, such as ceramic filter and corundum ball is also very important.

Sealant Adhesive

Sealants, adhesives, and other important products are widely used and have many applications. This requires the right conditions in terms of product viscosity (liquidity), curing speed, and cure time. Nano-materials have been used as modifiers in many foreign products. Nano-SiO2 has become the most popular. It is mostly coated with a thin layer of organic material to make nano-SiO2 more hydrophobic, and then added to the sealant. It is formed quickly, i.e., the Nano-SiOX small particles form a mesh structure that inhibits colloids from flowing, speeds up the curing, and enhances bonding. A small nano-SiO2 size increases both the sealing and the impermeability.

Glass Product

The FRP materials are light, have high strength and corrosion resistance but have poor wear resistance. Scientists use ultrasonic dispersion to add nano-SiO2 into the gelcoat resin. They then compare the performance of the gelcoat with and without the nano-SiO2. nano-SiO2 Wear resistance has increased 1 to 2 fold. Nanoparticles are grafted and bonded to organic polymers, increasing the toughness and impact resistance of the material. Heat resistance is greatly improved as well, as mentioned above.

(aka. Technology Co. Ltd. has over 12 years experience as a supplier and manufacturer of high-quality chemical materials. The nano-SiO2 Please note that the products produced by our company are of high purity and have low impurity content. Please. Contact us if necessary.