If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

1. Fundamental Qualities and Nanoscale Actions of Silicon at the Submicron Frontier

1.1 Quantum Confinement and Electronic Framework Makeover

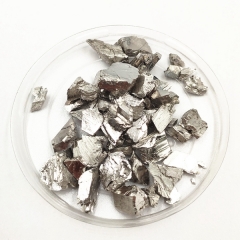

(Nano-Silicon Powder)

Nano-silicon powder, made up of silicon fragments with characteristic dimensions below 100 nanometers, represents a standard change from mass silicon in both physical actions and useful energy.

While mass silicon is an indirect bandgap semiconductor with a bandgap of around 1.12 eV, nano-sizing induces quantum confinement impacts that basically modify its electronic and optical buildings.

When the fragment size methods or falls listed below the exciton Bohr span of silicon (~ 5 nm), cost providers become spatially confined, causing a widening of the bandgap and the development of visible photoluminescence– a sensation lacking in macroscopic silicon.

This size-dependent tunability makes it possible for nano-silicon to emit light across the noticeable range, making it a promising candidate for silicon-based optoelectronics, where typical silicon falls short as a result of its poor radiative recombination effectiveness.

Moreover, the raised surface-to-volume proportion at the nanoscale improves surface-related sensations, consisting of chemical reactivity, catalytic activity, and communication with magnetic fields.

These quantum impacts are not just scholastic inquisitiveness yet form the structure for next-generation applications in energy, noticing, and biomedicine.

1.2 Morphological Diversity and Surface Chemistry

Nano-silicon powder can be manufactured in numerous morphologies, including round nanoparticles, nanowires, permeable nanostructures, and crystalline quantum dots, each offering distinctive advantages relying on the target application.

Crystalline nano-silicon usually preserves the diamond cubic structure of mass silicon yet exhibits a greater thickness of surface area issues and dangling bonds, which should be passivated to support the product.

Surface functionalization– typically attained with oxidation, hydrosilylation, or ligand attachment– plays a critical function in establishing colloidal security, dispersibility, and compatibility with matrices in composites or organic settings.

For example, hydrogen-terminated nano-silicon shows high sensitivity and is susceptible to oxidation in air, whereas alkyl- or polyethylene glycol (PEG)-covered particles show boosted security and biocompatibility for biomedical usage.

( Nano-Silicon Powder)

The presence of an indigenous oxide layer (SiOₓ) on the bit surface, even in marginal quantities, considerably influences electric conductivity, lithium-ion diffusion kinetics, and interfacial reactions, especially in battery applications.

Recognizing and regulating surface area chemistry is as a result necessary for harnessing the full capacity of nano-silicon in sensible systems.

2. Synthesis Methods and Scalable Fabrication Techniques

2.1 Top-Down Strategies: Milling, Etching, and Laser Ablation

The production of nano-silicon powder can be extensively categorized into top-down and bottom-up techniques, each with unique scalability, purity, and morphological control qualities.

Top-down methods include the physical or chemical reduction of mass silicon right into nanoscale fragments.

High-energy round milling is a commonly utilized industrial method, where silicon pieces undergo extreme mechanical grinding in inert atmospheres, causing micron- to nano-sized powders.

While cost-effective and scalable, this approach commonly introduces crystal problems, contamination from milling media, and broad bit size distributions, requiring post-processing purification.

Magnesiothermic reduction of silica (SiO TWO) complied with by acid leaching is another scalable course, particularly when utilizing natural or waste-derived silica resources such as rice husks or diatoms, providing a lasting pathway to nano-silicon.

Laser ablation and reactive plasma etching are more precise top-down techniques, with the ability of generating high-purity nano-silicon with regulated crystallinity, though at higher price and lower throughput.

2.2 Bottom-Up Methods: Gas-Phase and Solution-Phase Growth

Bottom-up synthesis permits better control over particle dimension, form, and crystallinity by developing nanostructures atom by atom.

Chemical vapor deposition (CVD) and plasma-enhanced CVD (PECVD) make it possible for the development of nano-silicon from aeriform forerunners such as silane (SiH FOUR) or disilane (Si two H ₆), with parameters like temperature level, pressure, and gas flow dictating nucleation and growth kinetics.

These methods are specifically effective for producing silicon nanocrystals embedded in dielectric matrices for optoelectronic devices.

Solution-phase synthesis, including colloidal paths making use of organosilicon substances, allows for the manufacturing of monodisperse silicon quantum dots with tunable emission wavelengths.

Thermal decomposition of silane in high-boiling solvents or supercritical liquid synthesis also yields top notch nano-silicon with narrow size distributions, ideal for biomedical labeling and imaging.

While bottom-up approaches typically produce remarkable material quality, they deal with obstacles in large-scale production and cost-efficiency, necessitating ongoing research right into hybrid and continuous-flow procedures.

3. Energy Applications: Reinventing Lithium-Ion and Beyond-Lithium Batteries

3.1 Duty in High-Capacity Anodes for Lithium-Ion Batteries

Among the most transformative applications of nano-silicon powder depends on power storage space, particularly as an anode product in lithium-ion batteries (LIBs).

Silicon uses an academic specific ability of ~ 3579 mAh/g based upon the development of Li ₁₅ Si Four, which is nearly 10 times more than that of standard graphite (372 mAh/g).

Nonetheless, the big volume expansion (~ 300%) throughout lithiation triggers fragment pulverization, loss of electrical contact, and continuous solid electrolyte interphase (SEI) formation, leading to rapid capability discolor.

Nanostructuring mitigates these issues by shortening lithium diffusion paths, accommodating pressure better, and minimizing crack chance.

Nano-silicon in the form of nanoparticles, permeable structures, or yolk-shell structures allows relatively easy to fix cycling with improved Coulombic effectiveness and cycle life.

Business battery technologies currently incorporate nano-silicon blends (e.g., silicon-carbon composites) in anodes to boost energy thickness in customer electronic devices, electric automobiles, and grid storage systems.

3.2 Potential in Sodium-Ion, Potassium-Ion, and Solid-State Batteries

Past lithium-ion systems, nano-silicon is being checked out in emerging battery chemistries.

While silicon is less responsive with sodium than lithium, nano-sizing enhances kinetics and allows limited Na ⁺ insertion, making it a prospect for sodium-ion battery anodes, especially when alloyed or composited with tin or antimony.

In solid-state batteries, where mechanical stability at electrode-electrolyte interfaces is important, nano-silicon’s ability to undergo plastic deformation at little ranges minimizes interfacial anxiety and boosts get in touch with upkeep.

Furthermore, its compatibility with sulfide- and oxide-based strong electrolytes opens methods for much safer, higher-energy-density storage space services.

Study continues to enhance user interface engineering and prelithiation approaches to make the most of the longevity and efficiency of nano-silicon-based electrodes.

4. Emerging Frontiers in Photonics, Biomedicine, and Compound Products

4.1 Applications in Optoelectronics and Quantum Light

The photoluminescent properties of nano-silicon have actually renewed efforts to establish silicon-based light-emitting tools, a long-lasting obstacle in integrated photonics.

Unlike mass silicon, nano-silicon quantum dots can exhibit efficient, tunable photoluminescence in the visible to near-infrared array, making it possible for on-chip lights suitable with corresponding metal-oxide-semiconductor (CMOS) modern technology.

These nanomaterials are being integrated into light-emitting diodes (LEDs), photodetectors, and waveguide-coupled emitters for optical interconnects and noticing applications.

In addition, surface-engineered nano-silicon shows single-photon discharge under certain problem configurations, positioning it as a prospective platform for quantum information processing and safe communication.

4.2 Biomedical and Environmental Applications

In biomedicine, nano-silicon powder is acquiring attention as a biocompatible, biodegradable, and safe alternative to heavy-metal-based quantum dots for bioimaging and medicine delivery.

Surface-functionalized nano-silicon particles can be made to target certain cells, launch therapeutic representatives in reaction to pH or enzymes, and supply real-time fluorescence tracking.

Their deterioration into silicic acid (Si(OH)₄), a normally taking place and excretable compound, minimizes long-lasting poisoning worries.

In addition, nano-silicon is being investigated for environmental remediation, such as photocatalytic degradation of pollutants under visible light or as a lowering representative in water therapy processes.

In composite materials, nano-silicon improves mechanical stamina, thermal stability, and wear resistance when integrated into steels, porcelains, or polymers, specifically in aerospace and auto elements.

To conclude, nano-silicon powder stands at the crossway of essential nanoscience and commercial development.

Its one-of-a-kind combination of quantum effects, high reactivity, and convenience throughout energy, electronic devices, and life scientific researches underscores its function as a crucial enabler of next-generation technologies.

As synthesis techniques advance and assimilation obstacles are overcome, nano-silicon will certainly remain to drive progression towards higher-performance, lasting, and multifunctional material systems.

5. Distributor

TRUNNANO is a supplier of Spherical Tungsten Powder with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about Spherical Tungsten Powder, please feel free to contact us and send an inquiry(sales5@nanotrun.com). Tags: Nano-Silicon Powder, Silicon Powder, Silicon

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us

Leave a Reply

You must be logged in to post a comment.