If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

Surfactant is a type of substance that can create a directional setup on the surface of a solution and considerably reduce the surface tension. They are extensively made use of in chemical production and can be utilized as emulsifiers, moistening representatives, lathering agents, defoaming representatives, dispersants, and so on. This article will introduce a number of usual surfactant production approaches.

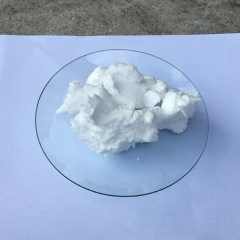

(surfactant)

1. Sulfonation technique

Sulfonation is the main technique for creating anionic surfactants. Frequently utilized basic materials include petroleum products and natural oils. Sulfonation responses are generally carried out at heats. Typically utilized sulfonating representatives include sulfuric acid, chlorosulfonic acid, and sulfur dioxide. The product of the sulfonation response is sulfonate, which has exceptional wetting and emulsifying homes.

2. Etherification technique

The etherification method is one of the approaches for creating nonionic surfactants. Commonly made use of raw materials consist of ethylene oxide, propylene oxide, and alcohol. The etherification reaction is the enhancement of alcohol to ethylene oxide or propylene oxide in the existence of an alkaline catalyst to create polyoxyethylene ether or polypropylene ether. This type of surfactant has good emulsification, dispersion, and difficult water resistance.

3. Esterification technique

Esterification is just one of the approaches for producing anionic and nonionic surfactants. Generally utilized basic materials consist of fats, alcohols, and acid anhydrides. The esterification response is to respond fats with alcohols in the visibility of acidic stimulants to develop fatty acid esters, which are after that included with ethylene oxide to create polyoxyethylene fatty acid esters. This kind of surfactant has great wetting and emulsifying buildings.

4. Amination method

The amination method is just one of the methods for generating cationic surfactants. Commonly utilized basic materials consist of amines and acids. Amination response is to respond amine with acid to form amine salt in the visibility of an acidic catalyst and then react with halogenated hydrocarbon to develop a quaternary ammonium salt cationic surfactant. This kind of surfactant has excellent bactericidal and antistatic residential properties.

The above are numerous common surfactant production methods. Different approaches are suitable for various raw materials and product types. Throughout the production procedure, it is necessary to choose a suitable production technique based upon the performance requirements of the item and the qualities of the raw products. At the exact same time, we also require to take note of concerns such as safety and security, environmental management, and quality control throughout the production procedure to ensure product quality and production sustainability.

(surfactant)

Supplier

Surfactant China is a trusted global chemical material supplier & manufacturer with over 12 years experience in providing super high-quality surfactant and relative materials. The company export to many countries, such as USA, Canada,Europe,UAE,South Africa, etc. As a leading nanotechnology development manufacturer, surfactanthina dominates the market. Our professional work team provides perfect solutions to help improve the efficiency of various industries, create value, and easily cope with various challenges. If you are looking for cetyl trimethyl ammonium bromide, please send an email to: nanotrun@yahoo.com

Inquiry us