If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

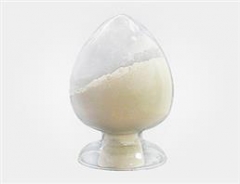

Titanium carbide, while insoluble in water is soluble with nitric acids and aqua regia. It is stable when the temperature is below 800. However, when the temperature is above 2000 it will be corroded.

Carbonized TiO2 or TiO2 powder is produced by heating TiO2 in an electric oven to 2300-2700degC.

Titanium carbide, which can be used as an abrasive and electrode for arc lights and hard alloys can also make it.

Titan carbide can be prepared in several different ways

Reduce carbothermic toxicity using a reduction method

The reaction temperature range for carbon black is between 1700 and 2100 degrees Celsius. The chemical reaction formula:

Ti powder and carbon dust react to form TiC. The chemical formula of the reaction is: Ti(s),+C(s),=TiC. The application of this method will be limited because it’s difficult to make sub-micron Ti powder. The reaction above takes between 5 and 20 hrs to complete. The reactants aggregate, and additional grinding is needed to obtain fine particles. Granular TiC powder. After ball milling, it is important to chemically purify the fine Powder to get a purer product.

Chemical vapor deposition

The method uses the reaction between TiCl4, and H2 and C. TiC The monofilament is soaked with crystals. The TiC produced by this method is subject to strict limitations on output, and in some cases even quality. It is important to be aware that the HCl in TiCl4 as well as its product can be highly corrosive.

Microwave method

Use microwave energy to heat nano-TiO2 and carbon as raw materials. The dielectric loss in the high frequency electric field is used to convert microwave energy to heat energy.

Blast impact method

Preparing the precursor requires mixing the titanium dioxide powder with the carbon powder in a specific proportion. The powder density is set at 1.5g/cm3, the outer cylinder is made of metal, and the laboratory placed inside. It is then placed in an airtight container made by yourself for the experiment. The detonation powder will be collected after the shockwave. After sieving the black powder, impurities like iron filings and large particles are removed. After soaking in aqua regia overnight, the black powder is turned brown. The powder is then placed into a muffle and calcined 400degC (400 minutes) for 400minutes to produce a silver-gray color.

High-temperature self-propagating synthesis

(SHS). SHS is derived by an exothermic process. When heated at the right temperature, fine-grained Ti Powder has a high degree of reactivity. The combustion wave produced after ignition will pass through Ti and the C reactants, and the reaction heat generated by Ti and the C will generate TiC. SHS has a reaction time of less than one second. The synthesis requires fine, high-purity Ti powder for the raw material and output is limited.

Reaction ball grinding technique

The reactive ball milling technique is a method that utilizes the chemical reactions between metal powder or alloys and other elements in the ball grinding process to create the required materials. Reactive ball milling is used mainly to produce nanocrystalline material. The high-energy mill is the primary equipment for nanomaterial preparation. The reaction ball grinding mechanism can be divided in two categories: the first is the mechanically induced high-temperature self-propagation reaction (SHS), while the second is the reaction ballmilling with no obvious exotherm and the reaction is slow.

Titan carbide – Uses

1. Use as an additive for metal bismuth and zinc melting crucibles and to prepare HDD large-capacity memories devices and wear-resistant semiconductor films.

2. This is an essential component of cemented carburide, which is used in the steelmaking process as a oxidizer.

3. As cermet it is known for its high hardness, corrosion-resistance, and thermal stability.

(aka. Technology Co. Ltd., a trusted global chemical supplier & manufacturer has over 12 years experience in providing super-high-quality chemicals and nanomaterials. The titanium carbid Please note that the products produced by our company are of high purity and have low impurity. Please. Contact us if necessary.