If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

Intro to Aluminum Nitride (AlN)

Light weight aluminum nitride (AlN), recognized for its extraordinary thermal conductivity, is emerging as a game-changer in the field of thermal management. With a substance name aluminum nitride and chemical formula AlN, this material shows remarkable residential or commercial properties that make it important in high-performance applications. This write-up discovers the structure, residential or commercial properties, applications, and future potential customers of light weight aluminum nitride, highlighting its transformative influence on numerous markets.

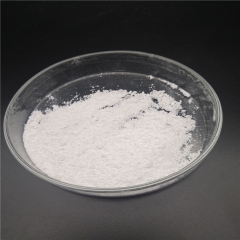

(TRUNNANO Aluminum Nitride Powder)

The Chemical Framework and Feature of Aluminum Nitride

Light weight aluminum nitride has the chemical formula AlN, including one light weight aluminum atom and one nitrogen atom. This structure presents a number of essential residential or commercial properties, including high thermal conductivity, exceptional electric insulation, and remarkable mechanical stamina. Light weight aluminum nitride’s thermal conductivity can reach up to 320 W/m · K, significantly more than several traditional products made use of in thermal monitoring. Its capacity to effectively dissipate heat makes it an ideal option for applications calling for fast and reliable thermal transfer. In addition, light weight aluminum nitride’s reduced coefficient of thermal development makes sure dimensional stability under differing temperatures, boosting integrity sought after settings.

Applications Throughout Various Sectors

1. Electronic devices and Semiconductors: In the electronics industry, light weight aluminum nitride’s high thermal conductivity plays a vital duty in managing warm dissipation from semiconductor devices. As power thickness increase in modern electronic devices, reliable thermal monitoring ends up being necessary to preserve efficiency and durability. Light weight aluminum nitride substratums and packaging materials give remarkable air conditioning remedies, minimizing thermal resistance and improving tool performance. This application is especially vital in high-power LEDs, where extreme warm can degrade efficiency and life expectancy. By properly dissipating heat, aluminum nitride allows brighter and more reliable LED illumination systems.

2. Power Electronic Devices and Automotive: The auto field advantages significantly from aluminum nitride’s thermal residential properties in power electronic devices applications. Electric automobiles (EVs) and hybrid electric lorries (HEVs) count on sophisticated power components that produce significant amounts of warm throughout operation. Light weight aluminum nitride substrates ensure reliable warmth elimination, preserving optimum operating temperatures and expanding the life of power electronics components. This is crucial for guaranteeing the reliability and efficiency of EV and HEV systems. Furthermore, light weight aluminum nitride’s light-weight nature adds to total car efficiency by decreasing weight without jeopardizing thermal monitoring capabilities.

3. Telecom and Optoelectronics: In telecommunications, aluminum nitride’s thermal conductivity enhances the efficiency of optoelectronic gadgets such as lasers and photodetectors. These tools call for exact temperature control to maintain steady result and protect against performance destruction. Aluminum nitride substratums use superb thermal administration, making sure consistent efficiency also under high-power problems. Additionally, its transparency in the ultraviolet (UV) to infrared (IR) variety enables efficient coupling of optical signals, making it suitable for integrated photonics applications. The assimilation of light weight aluminum nitride in telecom tools improves signal honesty and system dependability.

4. Space and Aerospace: The aerospace and area industries demand products that can endure extreme environmental conditions while supplying reliable thermal monitoring. Aluminum nitride’s high thermal conductivity and mechanical toughness make it an ideal candidate for satellite and spacecraft elements. Its capability to dissipate warm efficiently reduces the risk of getting too hot, which is critical for the longevity and efficiency of digital systems precede. Additionally, light weight aluminum nitride’s radiation resistance makes sure stable procedure in severe room atmospheres, boosting goal success rates. Making use of light weight aluminum nitride in these markets emphasizes its value in advancing space exploration and satellite technology.

Market Trends and Development Vehicle Drivers: A Progressive Perspective

1. Sustainability Initiatives: The global promote sustainable techniques has affected the development of eco-friendly materials. Aluminum nitride’s effectiveness in thermal management straightens with efforts to decrease power intake and boost system reliability. Manufacturers are progressively integrating light weight aluminum nitride right into eco-friendly technologies, driving market development. Innovations in recycling and resource-efficient production techniques additionally improve light weight aluminum nitride’s sustainability profile. As environmental awareness expands, the fostering of light weight aluminum nitride will remain to enhance, placing it as a principal in sustainable services.

2. Technological Advancements in Electronics: Rapid improvements in electronic devices require higher-performance products efficient in meeting strict requirements. Aluminum nitride’s duty in thermal administration guarantees its significance in next-generation innovations. Technologies in 5G networks, expert system, and quantum computing rely on aluminum nitride’s thermal conductivity to achieve optimum efficiency. The assimilation of aluminum nitride in these cutting-edge applications showcases its flexibility and future-proof nature. As electronics advance, light weight aluminum nitride stays at the forefront of technological advancement.

3. Healthcare Development: Increasing healthcare expense, driven by maturing populaces and boosted wellness understanding, enhances the demand for advanced medical remedies. Aluminum nitride’s multifunctional buildings make it an eye-catching component in medical devices and analysis devices. Its ability to successfully handle warmth boosts the performance and safety and security of medical tools, guaranteeing reputable client treatment. The trend in the direction of miniaturization and mobility favors light weight aluminum nitride’s portable and efficient thermal monitoring capabilities. As healthcare continues to prioritize innovation and patient-centric solutions, aluminum nitride’s duty ahead of time medical innovations can not be overemphasized.

Obstacles and Limitations: Browsing the Path Forward

1. Production Prices: Regardless of its benefits, the manufacturing process for aluminum nitride can be complex and costly. High-purity light weight aluminum nitride needs accurate synthesis strategies, bring about greater manufacturing prices contrasted to typical materials. However, ongoing r & d aim to optimize making processes, lowering prices and enhancing availability. Advancements wholesale synthesis and thin-film deposition techniques promise to make light weight aluminum nitride much more financially viable for widespread adoption. Attending to production challenges will certainly be important for increasing the market reach of light weight aluminum nitride.

( Aluminum Nitride Powder)

2. Technical Experience: Successfully integrating light weight aluminum nitride right into styles requires specialized understanding and handling techniques. Small makers or those unfamiliar with its properties could deal with difficulties in maximizing light weight aluminum nitride usage without sufficient expertise and devices. Bridging this void via education and available innovation will be necessary for wider fostering. Empowering stakeholders with the needed skills will open light weight aluminum nitride’s complete possible across sectors.

Future Prospects: Advancements and Opportunities

The future of the light weight aluminum nitride market looks encouraging, driven by boosting demand for high-performance and sustainable products. Recurring r & d will cause the production of brand-new qualities and applications for light weight aluminum nitride. Innovations in nanotechnology, eco-friendly products, and environment-friendly chemistry will certainly even more enhance its worth proposition. As industries prioritize performance, durability, and environmental responsibility, aluminum nitride is positioned to play an essential duty in shaping the future of electronics, vehicle, telecommunications, and past. The constant evolution of light weight aluminum nitride assures amazing chances for advancement and growth.

Verdict: Accepting the Potential of Aluminum Nitride

To conclude, light weight aluminum nitride (AlN) is a functional and crucial material with varied applications in electronic devices, automotive, telecommunications, and aerospace. Its phenomenal thermal conductivity provides considerable advantages, driving market growth and technology. Recognizing the benefits and challenges of aluminum nitride enables stakeholders to make enlightened decisions and profit from arising chances. Embracing light weight aluminum nitride implies accepting a future where innovation fulfills integrity and sustainability in modern-day industry.

High-quality Aluminum Nitride Distributor

TRUNNANO is a supplier of boron nitride with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about aluminum nitride hardness, please feel free to contact us and send an inquiry(sales5@nanotrun.com).

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us