If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

Introduction to Titanium Carbide TiC Powder Titanium carbide (TiC) powder is an amazing material that incorporates the strength and solidity of titanium with the sturdiness and use resistance of carbon. With its compound name TiC, this ceramic-metal hybrid displays outstanding properties, making it vital in numerous sophisticated applications. This post discovers the composition, manufacturing methods, applications, and future potential customers of titanium carbide powder, highlighting its transformative effect on modern-day markets.

The Chemical Framework and Properties of Titanium Carbide

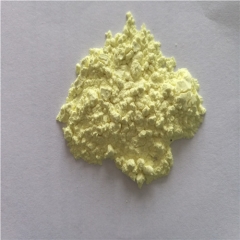

(Titanium Carbide Powder)

Titanium carbide has the chemical formula TiC, containing one titanium atom bonded to one carbon atom. This structure presents a number of superior residential properties, including severe solidity, high melting factor, outstanding thermal conductivity, and exceptional wear resistance. TiC develops a face-centered cubic crystal structure comparable to that of diamond, which adds to its outstanding mechanical properties. Its capacity to withstand severe temperatures and stress makes titanium carbide powder appropriate for demanding atmospheres where standard materials would stop working.

Manufacturing Techniques and Difficulties

The production of titanium carbide powder includes complicated procedures focused on achieving high pureness and regular fragment size. Usual methods consist of carbothermal reduction, straight carbonization, and chemical vapor deposition (CVD). Carbothermal reduction includes responding titanium dioxide (TiO ₂) with carbon at elevated temperature levels, causing the development of TiC. Straight carbonization entails home heating metal titanium with carbon under controlled problems. CVD creates high-purity TiC by decomposing aeriform forerunners onto a warmed substrate. Each approach has its advantages and difficulties, needing accurate control over temperature level, stress, and reactant proportions to make certain ideal top quality. Advances in synthesis strategies remain to enhance the efficiency and scalability of TiC powder production.

Applications Across Numerous Sectors

1. Hardmetals and Reducing Devices: Titanium carbide powder is extensively utilized in the manufacturing of hardmetals, also called concrete carbides. These materials combine TiC with binders like cobalt or nickel to create ultra-hard cutting tools. TiC’s extraordinary hardness and put on resistance boost device performance, prolonging life span and minimizing upkeep expenses. Hardmetal elements including TiC are extensively used in machining procedures, mining, and building, where they supply premium sturdiness and dependability.

2. Coatings and Surface Treatments: TiC finishings give improved security versus wear, deterioration, and thermal destruction. Applied through physical vapor deposition (PVD) or CVD, these finishes form a durable layer on steel surfaces, improving their mechanical residential properties. TiC-coated tools and components display longer life expectancies and greater efficiency, making them ideal for aerospace, automobile, and making applications. The advancement of innovative layer modern technologies continues to expand the utility of TiC in surface area treatments.

3. Electronic devices and Semiconductors: In the electronic devices market, titanium carbide powder plays a vital role in semiconductor manufacture. Its high thermal conductivity and reduced electrical resistivity make TiC suitable for heat sinks and interconnects in incorporated circuits. In addition, TiC nanoparticles are used in the advancement of next-generation electronic devices, providing enhanced performance and miniaturization. The assimilation of TiC in electronic components underscores its significance in driving technology and efficiency in the technology field.

4. Medical and Oral Implants: Titanium carbide’s biocompatibility and mechanical strength make it an attractive material for medical and dental implants. TiC-based finishes enhance the sturdiness and longevity of implantable tools, ensuring individual safety and efficacy. Making use of TiC in orthopedic and dental applications supplies substantial advantages over conventional products, promoting faster healing times and better medical outcomes. Developments in biomedical engineering remain to check out new possibilities for TiC in medical care solutions.

Market Patterns and Development Chauffeurs: A Forward-Looking Viewpoint

1. Sustainability Campaigns: The worldwide promote sustainable methods has actually affected the development of eco-friendly materials. Titanium carbide powder lines up well with sustainability objectives due to its sturdiness and lengthy service life, decreasing the demand for constant substitutes. Producers are discovering means to lessen ecological effects throughout TiC production, such as optimizing power intake and recycling waste products. Innovations in green chemistry and resource-efficient procedures will certainly additionally boost TiC’s sustainability account.

2. Technological Developments in Manufacturing: Rapid developments in manufacturing modern technology demand products with the ability of conference rigid efficiency needs. Titanium carbide powder’s remarkable properties placement it as a principal in advanced applications. Advancements in additive manufacturing, 3D printing, and nanotechnology are expanding TiC’s application possibility, enabling the development of complex geometries and high-performance components. The assimilation of TiC in advanced production procedures showcases its flexibility and future-proof nature.

(Titanium Carbide Powder)

3. Medical Care Advancement: Climbing health care expenditure, driven by maturing populaces and raised health understanding, boosts the need for innovative clinical remedies. Titanium carbide’s multifunctional homes make it an attractive element in clinical devices and implants. The trend towards personalized medicine and minimally intrusive therapies prefers TiC’s accuracy and biocompatibility. As medical care continues to prioritize advancement and patient-centric solutions, TiC’s duty in advancing medical technologies can not be overstated.

Obstacles and Limitations: Navigating the Course Forward

1. Manufacturing Expenses and Technical Competence: Making high-quality titanium carbide powder requires specific tools and experience, leading to higher manufacturing prices. Small manufacturers or those not familiar with TiC synthesis could face obstacles in maximizing production without appropriate sources and understanding. Bridging this gap with education and obtainable modern technology will certainly be necessary for wider adoption. Equipping stakeholders with the needed abilities will unlock TiC’s complete possible throughout markets.

2. Environmental Worries: In spite of its benefits, the production of titanium carbide can have ecological impacts. Emissions from synthesis procedures and disposal of waste materials increase worries about air quality and resource deficiency. Regulatory bodies are implementing more stringent standards to minimize these results, motivating suppliers to embrace sustainable techniques. Addressing ecological challenges will be important for the proceeded use and market approval of titanium carbide. Innovations in eco-friendly chemistry and procedure optimization can aid stabilize efficiency with ecological obligation.

Future Prospects: Innovations and Opportunities

The future of the titanium carbide market looks appealing, driven by boosting need for high-performance and sustainable materials. Ongoing r & d will result in the production of new qualities and applications for TiC powder. Innovations in additive manufacturing, nanotechnology, and eco-friendly chemistry will certainly better improve its worth proposal. As markets prioritize efficiency, sturdiness, and environmental responsibility, titanium carbide is poised to play a crucial role fit the future of manufacturing, electronic devices, health care, and past. The continual evolution of TiC guarantees amazing chances for innovation and development.

Conclusion: Embracing the Potential of Titanium Carbide TiC Powder

To conclude, titanium carbide (TiC) powder is a functional and necessary product with extensive applications in hardmetals, finishings, electronics, and medical care. Its special homes and abundant schedule offer significant advantages, driving market development and technology. Understanding the benefits and obstacles of TiC enables stakeholders to make enlightened choices and take advantage of emerging chances. Welcoming titanium carbide implies accepting a future where technology satisfies dependability and sustainability in modern industry.

Distributor

Mycarbides is a trusted global chemical material supplier & manufacturer with over 12 years experience in providing super high-quality carbides and relative materials. The company export to many countries, such as USA, Canada,Europe,UAE,South Africa, etc. As a leading nanotechnology development manufacturer, mycarbides dominates the market. Our professional work team provides perfect solutions to help improve the efficiency of various industries, create value, and easily cope with various challenges. If you are looking for compound of titanium, please send an email to: nanotrun@yahoo.com Tags: Titanium Carbide, TiC Powder, titanium uses

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us