If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

Introduction to Stainless-steel SS316L Powder

Stainless-steel SS316L powder is a high-quality product understood for its extraordinary deterioration resistance, toughness, and versatility. This austenitic stainless steel grade consists of molybdenum, which enhances its resistance to chloride ion corrosion, making it suitable for marine, chemical handling, and medical applications. This post discovers the composition, manufacturing processes, applications, market fads, and future leads of SS316L powder, highlighting its transformative effect on contemporary markets.

(Stainless Steel SS316L 3D Printed Products)

Composition and Production Process

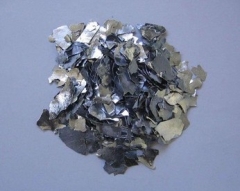

Stainless Steel SS316L is composed mostly of iron, chromium, nickel, and molybdenum, with low carbon material (usually 0.03% max) to enhance weldability and minimize the danger of intergranular corrosion. The production of SS316L powder includes a number of actions. First, basic materials are meticulously chosen and blended in exact proportions to attain the wanted alloy make-up. The blend is after that melted utilizing electrical arc furnaces or induction melting methods. As soon as molten, the metal is atomized right into great fragments through gas atomization or water atomization approaches. Gas atomization makes use of inert gases like nitrogen or argon to cool and strengthen the liquified metal right into consistent round bits. Water atomization entails spraying molten metal right into a water chamber, leading to irregularly shaped particles. Post-atomization treatments, including sieving and drying, make certain constant bit size distribution and pureness. The result is a robust powder with superb mechanical residential properties, prepared for various applications.

Applications Across Different Sectors

Additive Production: In the area of additive manufacturing (AM), SS316L powder is thoroughly made use of as a result of its superb printability and mechanical properties. It is employed in discerning laser sintering (SLS), straight metal laser sintering (DMLS), and binder jetting processes to produce complicated geometries that would certainly be difficult or impossible to create with traditional manufacturing techniques. AM makes it possible for fast prototyping, personalized components, and light-weight styles, making SS316L powder indispensable for aerospace, vehicle, and medical markets.

Medical Devices: The clinical industry advantages considerably from SS316L powder’s biocompatibility and corrosion resistance. It is made use of in the production of medical instruments, orthopedic implants, and dental gadgets. SS316L’s capacity to stand up to deterioration in bodily fluids makes certain long-term efficiency and safety and security. In addition, its non-magnetic homes make it suitable for MRI-compatible gadgets. Makers take advantage of these residential properties to establish innovative clinical options that improve individual care and end results.

Chemical Handling: SS316L powder is widely utilized in chemical handling plants due to its remarkable resistance to harsh environments. It is utilized in reactors, warm exchangers, and piping systems where direct exposure to aggressive chemicals and heats is common. SS316L’s molybdenum material offers boosted resistance to matching and crevice deterioration, guaranteeing reputable operation and extended equipment life. Chemical suppliers depend on SS316L powder to fulfill stringent security and efficiency criteria.

Marine and Offshore: The marine and offshore fields use SS316L powder for elements subjected to deep sea and severe marine atmospheres. It is used in shipbuilding, offshore systems, and underwater devices where deterioration resistance is important. SS316L’s capacity to hold up against chloride ion assault makes it an optimal selection for these requiring applications. Marine engineers and designers integrate SS316L powder to construct sturdy frameworks that can run effectively in difficult conditions.

Market Patterns and Development Drivers: A Forward-Looking Viewpoint

Technological Innovations: Innovations in product scientific research and production technologies have broadened the capabilities of SS316L powder. Advanced atomization methods enhance fragment morphology and dimension distribution, enhancing printability and mechanical residential properties. Additive production permits complicated geometries and customized designs, meeting varied application requirements. The integration of smart sensors and automation in production lines increases effectiveness and quality assurance. Makers adopting these innovations can supply higher-performance SS316L powders that satisfy rigorous market criteria.

Sustainability Initiatives: Environmental understanding has driven demand for sustainable products and practices. SS316L powder straightens well with sustainability goals as a result of its recyclability and energy-efficient buildings. Recycling SS316L reduces the need for key mining, conserving natural deposits and reducing environmental influence. Producers are checking out green manufacturing methods and energy-efficient processes to decrease waste and exhausts. Developments in waste decrease and resource optimization better boost the sustainability account of SS316L powder. As sectors prioritize eco-friendly initiatives, the adoption of recycled SS316L will certainly remain to expand, placing it as a principal in eco-conscious options.

Health Care Technology: Increasing medical care expenditure and an aging population boost the demand for sophisticated medical tools. SS316L powder’s biocompatibility and accuracy make it vital in establishing cutting-edge clinical remedies. Customized medicine and minimally intrusive treatments favor sturdy and trusted materials like SS316L. Makers focusing on health care advancement can capitalize on the growing market for medical-grade SS316L, driving development and distinction.

( Stainless Steel SS316L 3D Printed Products)

Challenges and Limitations: Browsing the Path Forward

High First Prices: One difficulty associated with SS316L powder is its fairly high initial expense compared to standard materials. The complicated manufacturing procedure and specific equipment add to this expense. However, the remarkable efficiency and extended lifespan of SS316L frequently warrant the investment over time. Suppliers must consider the ahead of time costs against long-term advantages, considering aspects such as reduced downtime and improved item quality. Education and demo of worth can help overcome expense obstacles and advertise broader fostering.

Technical Experience and Handling: Correct usage and upkeep of SS316L powder need specialized knowledge and skill. Operators require training to take care of these precision tools efficiently, guaranteeing optimal performance and long life. Small-scale manufacturers or those not familiar with innovative machining methods might face difficulties in maximizing device usage. Bridging this gap through education and easily accessible technical support will be important for more comprehensive fostering. Empowering stakeholders with the needed abilities will certainly unlock the complete capacity of SS316L powder across industries.

Future Prospects: Developments and Opportunities

The future of SS316L powder looks encouraging, driven by increasing need for high-performance products and progressed production modern technologies. Ongoing research and development will certainly result in the production of new qualities and applications for SS316L powder. Advancements in nanostructured alloys, composite products, and surface engineering will additionally improve its efficiency and broaden its utility. As sectors focus on precision, performance, and sustainability, SS316L powder is poised to play a crucial role in shaping the future of manufacturing and modern technology. The continual development of SS316L powder guarantees interesting opportunities for technology and development.

Conclusion: Welcoming the Precision Revolution with SS316L Powder

In conclusion, SS316L powder represents a keystone of accuracy engineering, supplying unparalleled corrosion resistance, durability, and adaptability for requiring applications. Their comprehensive applications in additive manufacturing, medical devices, chemical handling, and marine atmospheres highlight their relevance. Understanding the advantages and obstacles of SS316L powder makes it possible for suppliers to make enlightened decisions and capitalize on arising chances. Accepting SS316L powder suggests welcoming a future where accuracy satisfies integrity and development in modern-day manufacturing.

Vendor

TRUNNANO is a supplier of Stainless Steel SS316L Powder with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about Nano-copper Powder, please feel free to contact us and send an inquiry(sales5@nanotrun.com).

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us