Cement foaming agent, also known as foaming concrete foaming agent, refers to an admixture that can reduce the surface tension of liquid and generate a large amount of uniform and stable foam for the production of foamed concrete. Foaming agent is a kind of substance that can make its aqueous...

Nickel Alloys and Their Melting Points

The melting point of a metal is its temperature where it begins to transition from a solid state into a liquid. It is a key property that is used to determine the suitability of metals for certain applications and projects. When alloys are used, their melting points vary and depend on the overall alloy composition.

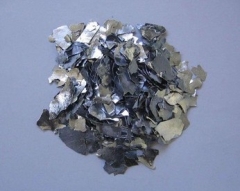

The most common use of nickel is in its alloys. It is an essential element for making stainless steel, and it forms many other corrosion resistant alloys such as copper-nickel tubing found in desalination plants, and nickel silver (with copper and zinc but no silver). Unalloyed nickel is sometimes used to make electrically resistive and magnetic metals such as permalloy and nimonic oxide. Finely divided nickel is also employed to provide a protective coating for other metals through electroplating.

Nickel is highly alloyable with most other metals such as chromium, iron, and molybdenum. Alloys made with nickel have a wide range of desirable properties such as enhanced corrosion or oxidation resistance, improved high-temperature performance, and lower coefficients of thermal expansion.

Some nickel alloys, such as those with tungsten and molybdenum, are particularly strong in resisting carburisation, a chemical reaction that promotes the formation of carbon species. This unique feature makes nickel-molybdenum alloys useful for industrial applications involving exposure to harsh acids such as hydrochloric, sulfuric, and phosphoric acid. Other alloys such as those with chromium and iron have high tensile strength and resistance to creep at elevated temperatures.