C6 Alkyl glucoside CAS 54549-24-5

About C6 Alkyl glucoside:

C6 Alkyl glucoside is usually 75% aqueous, neutral, or weakly alkaline. Amber liquid.Low surface tension, good detergency; Low carbon alcohol APG, no foam, and has a more obvious defoaming effect on the formula system; It has good water solubility, and it can dissolve some other compounds that are not easily soluble in water.Resistance to strong alkali, high temperature, and high concentration electrolyte; Biodegradable.

Biomedicalmaterialsprogram is a trusted global C6 Alkyl glucoside. Feel free to send an inquiry to get the latest price of C6 Alkyl glucoside. If you would like to buy C6 Alkyl glucoside in bulk.

Product Performance of C6 Alkyl glucoside:

C6 Alkyl glucoside is usually 75% aqueous, neutral, or weakly alkaline. Amber liquid.Low surface tension, good detergency; Low carbon alcohol APG, no foam, and has a more obvious defoaming effect on the formula system; It has good water solubility, and it can dissolve some other compounds that are not easily soluble in water.Resistance to strong alkali, high temperature, and high concentration electrolyte; Biodegradable.

Technical Parameter of C6 Alkyl glucoside:

| Product name | C6 Alkyl glucoside |

| Short name | N/A |

| Appearance | Amber liquid |

Application of C6 Alkyl glucoside:

Suitable for mechanical cleaning, beer bottle cleaning related to food production field cleaning agent, drier; Alkali resistant and high-temperature resistant textile scouring agent; Steel plate cleaning agent, etc.

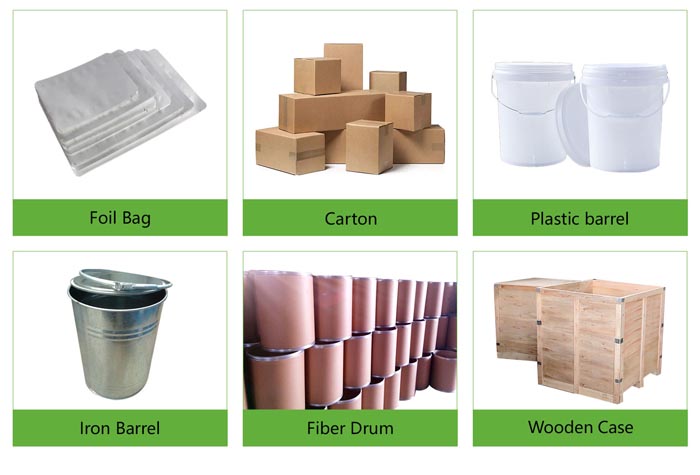

Packing & Shipping of C6 Alkyl glucoside:

We have many different kinds of packing which depend on C6 Alkyl glucoside quantity.

C6 Alkyl glucoside packing: 1kg/bottle, 25kg/barrel, or 200kg/ barrel.

C6 Alkyl glucoside shipping: could be shipped out by sea, by air, by express as soon as possible once payment receipt.

C6 Alkyl glucoside Properties | |

| Other Names | Hexyl glucoside; APG06 |

| CAS No. | 54549-24-5 |

| Compound Formula | (C6H11O5)nOR R=C6 n=1.2-1.3 |

| Molecular Weight | N/A |

| Appearance | Amber liquid |

| Melting Point | N/A |

| Boiling Point | N/A |

| Density | N/A |

| Solubility in H2O | N/A |

| Exact Mass | N/A |

| C6 Alkyl glucoside Health& Safety Information | |

| Signal Word | N/A |

| Hazard Statements | N/A |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety Statements | N/A |

| Transport Information | N/A |

Inquiry us