Lithium Battery Anode Material 99.95% Natural Composite Graphite 216

About Lithium Battery Anode Material 99.95% Natural Composite Graphite 216:

Natural graphite is a natural mineral, which is generally formed in high-temperature geological conditions and widely distributed in metamorphic deposits. It is formed by the regional metamorphism of sedimentary rocks rich in organic matter or carbon. Generally can be divided into crystalline graphite (flake) and cryptocrystalline graphite (earthy)

The technological properties and uses of graphite are mainly determined by the degree of crystallization. Natural graphite can be divided into crystalline graphite (flake graphite) and cryptocrystalline graphite (earthy graphite) according to its crystalline form.

Crystalline graphite

In crystalline (flaky) graphite ores, the graphite crystals are larger than 1μm in diameter and are flaky. The ore grade is low, but the benefits ability is good. The minerals associated with graphite are often mica, feldspar, quartz, tremolite, diopside, garnet and a small amount of pyrite, calcite, etc., and some are associated with rutile and vanadium and other useful components; The ore is of flake, granitic scale or granular last crystalline structure, flake, gneiss or massive structure.

Cryptocrystalline graphite

Cryptotite ink is also known as earth-like graphite or amorphous graphite. In cryptocrystalline graphite ore, graphite crystal diameter is less than 1μm, showing an aggregate of microcrystals, and crystal shape can be seen under an electron microscope; The ore has high grade but poor separability. The minerals associated with graphite are often quartz, calcite, etc. The ore has a fine-scale - cryptocrystalline structure, massive or soil-like structure. Biomedicalmaterialsprogram is a trusted global Lithium Battery Anode Material 99.95% Natural Composite Graphite 216 supplier. Feel free to send an inquiry about the latest price of Natural Composite Graphite 216 at any time.

Performance of Anode Material 99.95% Natural Composite Graphite 216 :

Natural composite graphite 216 has the characteristics of high energy density, long life and low expansion.

Technical Parameter of Anode Material 99.95% Natural Composite Graphite 216 :

| Product Number | Particle Size ( D50 ) | TAP | SSA | Gram Capacity | Compacted density |

| Tr-216 | 14um | 1.1±0.1 g/cc | 2.0±0.5 m2/g | 365-367 mAH/g | 1.67 |

How is Lithium Battery Anode Material 99.95% Natural Composite Graphite 216 Produced?

The invention discloses a preparation method of natural graphite-based composite electrode material. In this method, the micro-oxidized natural graphite was mixed with the stage products of pyrolysis carbon of melamine at a certain mass ratio, and then the natural graphite matrix composites with high performance were obtained after the ball milling and screening.

Applications of Lithium Battery Anode Material 99.95% Natural Composite Graphite 216:

Natural graphite is naturally formed graphite. Natural graphite is an important industrial mineral, which is used in almost every aspect of the manufacturing industry, including electronics, atomic energy, molten iron processing, friction, coating, aerospace, powder metallurgy, etc.

Storage Condition of Anode Material 99.95% Natural Composite Graphite 216 :

a Carbon graphite composite 216 should be stored in a dry, ventilated place without other sources of pollution (recommended: temperature ≤45℃, humidity ≤85%);

b Natural composite graphite 216 stacking should be neat and tidy, and the production batch number, production date and other signs should be clearly identifiable;

c Handle with care during transportation to avoid damage to the packaging; Natural composite graphite 216 that leaks out of the package should not be returned to the box.

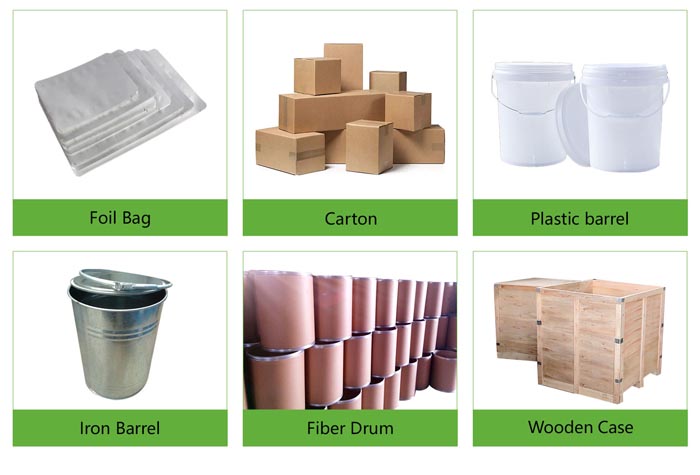

Packing & Shipping of Anode Material 99.95% Natural Composite Graphite 216 :

We have many different kinds of packing which depend on the natural composite graphite 216 quantity.

Natural composite graphite 216 packing: 1kg/bag or 5kg/bag, 25kg/carton, or as your request.

Natural composite graphite 216 shipping: could be shipped out by sea, by air, by express as soon as possible once payment receipt.

Natural Composite Graphite Powder Properties | |

| Other Names | Natural composite graphite 216, graphite, msds |

| CAS No. | N/A |

| Compound Formula | N/A |

| Molecular Weight | N/A |

| Appearance | N/A |

| Melting Point | N/A |

| Solubility in water | N/A |

| Density | 1.67 |

| Purity | 99.95% |

| Particle Size | 14um |

| Boling point | N/A |

| Specific Heat | N/A |

| Thermal Conductivity | N/A |

| Thermal Expansion | N/A |

| Young's Modulus | N/A |

| Exact Mass | N/A |

| Monoisotopic Mass | N/A |

Natural Composite GraphitePowder Health & Safety Information | |

| Safety Warning | N/A |

| Hazard Statements | N/A |

| Flashing point | N/A |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety Statements | N/A |

| RTECS Number | N/A |

| Transport Information | N/A |

| WGK Germany | N/A |

Inquiry us