CAS 1592-23-0 Calcium Stearate Powder

About Calcium Stearate Powder:

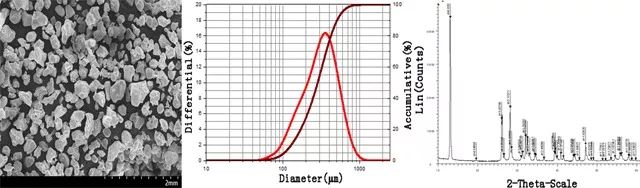

Calcium Stearate Powder is a fine white, fluffy powder with a smooth hand feel, soluble in toluene, ethanol and other organic solvents.

Biomedicalmaterialsprogram is a trusted global Calcium Stearate Powder. Feel free to send an inquiry to get the latest price of Calcium Stearate Powder if you would like to buy Calcium Stearate Powder in bulk.

If you want to know calcium stearate price, please send inquiry to sales1@rboschco.com

Product Performance of Calcium Stearate Powder:

Calcium Stearate Powder is widely used in food, medicine, cosmetics, plastics, rubber and other industries, mainly as lubricants, emulsifiers, stabilizers, mold release agents, accelerators, cosmetic base materials, etc.

Technical Parameter of Calcium Stearate Powder:

| Product Name | Short Name | Melting Point | Ca Content | Particle Size | Appearance |

|---|---|---|---|---|---|

| Calcium Stearate Powder | N/A | 140-158℃ | 6.5±0.6% | 325 mesh, 200 mesh | white powder |

Applications of Calcium Stearate Powder:

Calcium stearate powder can improve the coagulation speed in rigid plastic products, and can also be used for non-toxic soft films such as food packaging and medical equipment. It also has the effect of stabilizer and has good long-term stability.

Calcium stearate powder is used as a stabilizer and lubricant in polyethylene and polyvinyl chloride, and as a halogen absorber in polyethylene and polypropylene, which can eliminate the adverse effects of the catalyst remaining in the resin on the color and stability of the resin.

Calcium stearate uses in pvc, Calcium stearate powder is used to improve the heat resistance of plastics, improve the initial coloring property and air permeability of weather resistance, and will replace the toxic stabilizer with the same properties.

Packing & Shipping of Calcium Stearate Powder:

We have many different kinds of packing which depend on Calcium Stearate Powder quantity.

Calcium Stearate Powder packing: 20kg/bag, then put on pallet.

Calcium Stearate Powder shipping: could be shipped out by sea, by air, by express as soon as possible once payment receipt.

Calcium Stearate Powder Properties | |

| Other Names | N/A |

| CAS No. | 1592-23-0 |

| Compound Formula | Ca[CH3(CH2)16COO]2 |

| Molecular Weight | N/A |

| Appearance | White powder |

| Melting Point | 140-158℃ |

| Boiling Point | N/A |

| Density | N/A |

| Solubility in H2O | No |

| Exact Mass | N/A |

Calcium Stearate Powder Health & Safety Information | |

| Signal Word | N/A |

| Hazard Statements | N/A |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety Statements | N/A |

| Transport Information | N/A |

Inquiry us