Cement foaming agent, also known as foaming concrete foaming agent, refers to an admixture that can reduce the surface tension of liquid and generate a large amount of uniform and stable foam for the production of foamed concrete. Foaming agent is a kind of substance that can make its aqueous...

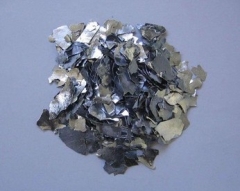

What is Silicon Boride Powder?

Silicon hexaboride is also known as hexaboron Silicide. It's a glossy, black-gray powder. SiB6 is its chemical formula. The molecular weight of SiB6 is 92.95. The relative density of the material is 2.47 g/cm3, and its melting point is 2200. It is roughly the same hardness as ruby or diamond. Silicon hexaboride is capable of conducting electricity. It is insoluble when water is used. It can be oxidized when heated in chlorine or water vapor.

Silicon Boride Powder's Physicochemical Property

The SiB6 crystal structure includes interconnected icosahedrons, polyhedrons that have 20 faces and icosahedrons that have 26 faces. It also contains isolated silicon and bore atoms.

It is insoluble when it comes into contact with water, and is resistant to oxidation and thermal shock. It has high strength, stability, and resistance to thermal shock. The grinding efficiency of this product is superior to boron carbide.

Surface oxidation is caused by SiB6 being heated in oxygen or air. SiB6 can then be eroded at high temperatures using boiling sulfuric and fluorine, chlorin, and bromine. Borides can be used as electrical conductors. Hexamborides are low in thermal expansion and have high thermal neutron cross sections.

| Silicon Boride Powder Properties | |

| Other Names | SiB6 Powder, silicon hexaboride |

| CAS No. | 12008-29-6 |

| Formula compound | SiB6 |

| Molecular Weight | 92.95 |

| Appearance | From dark grey to black powder |

| Melting Point | 1950 |

| Boiling Point | N/A |

| Density | 2.43g/cm3 |

| Solubility of H2O | Insoluble |

| Exact Mass | 93.04 |

Preparation methods for Silicon Boride Powder

The mixture of boron, silicon, and water can be heated directly. Any excess silicon can then be removed with HNO3 and HF. Molten KOH can then be used to decompose the B3Si.

Silicon Boride Powder: Applications

1 Used to grind cemented carbide, standard abrasives, and other uses.

2 are used for engineering ceramic material and sandblasting, as well as manufacturing gas engine blades and special-shaped sintering parts.

3. It is used as an oxidant in refractories.

Main supplier of Silicon Boride powder

Technology Co. Ltd. is a trusted global supplier and manufacturer of chemical materials. We have more than 12 years experience in producing super-high-quality chemicals.

High-quality products are what you want Silicon Boride Powder, Feel free to contact us by sending an inquiry. (brad@ihpa.net)